How to Choose the Right CNC Boring Mill for Your Manufacturing Needs

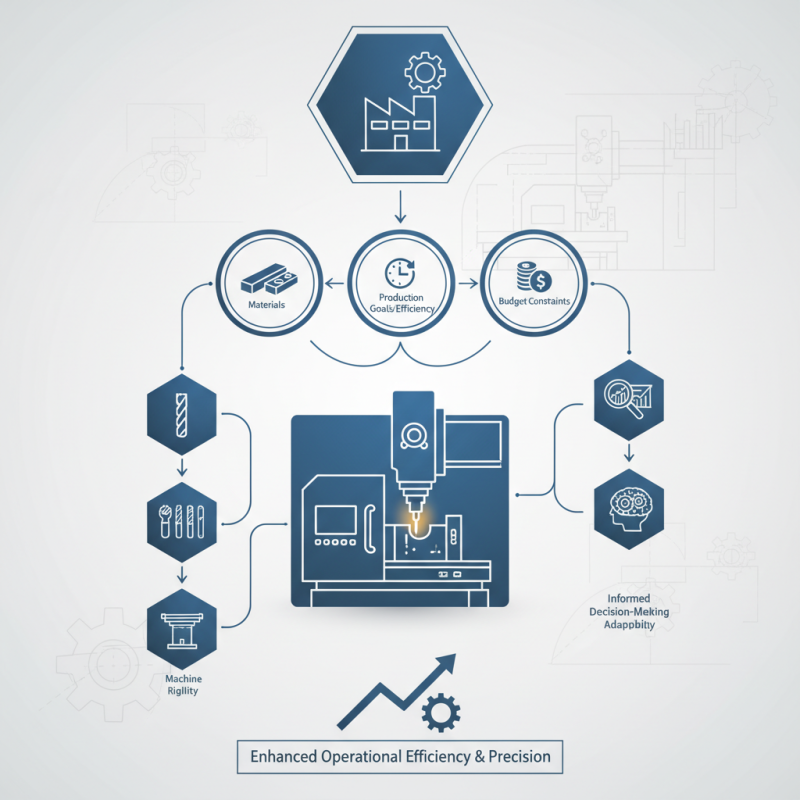

In today's competitive manufacturing landscape, selecting the right CNC boring mill is crucial for enhancing operational efficiency and precision. According to a recent industry report by the Association for Manufacturing Technology, the CNC machining market is projected to reach $100 billion by 2026, driven by advances in automation and demand for high-quality components. The CNC boring mill, known for its capability to machine deep holes with precision, plays a pivotal role in this growth, underscoring the importance of informed decision-making in equipment procurement.

Industry expert Dr. James Anderson, a leading authority in CNC technology, emphasizes the significance of this choice: "Choosing the right CNC boring mill is not just about specifications; it's about understanding your unique manufacturing needs and the types of materials you will be working with." This sentiment resonates with many manufacturers seeking to optimize their production processes while maintaining cost-effectiveness. Understanding factors such as spindle speed, cutting tools, and machine rigidity can make a substantial difference in achieving desired outcomes and maximizing return on investment.

Ultimately, the choice of a CNC boring mill should align closely with specific production goals, material requirements, and budget constraints. As the industry evolves, staying informed and adaptable will be key for manufacturers aiming to leverage the full potential of CNC technology in their operations.

Understanding CNC Boring Mills and Their Applications

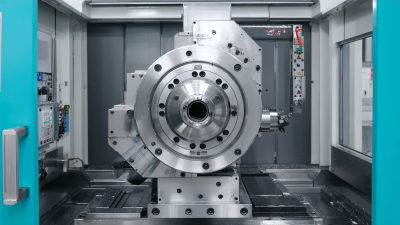

CNC boring mills are essential tools in modern manufacturing, designed to refine and enhance the precision of large workpieces through the boring and finishing processes. Their primary capabilities include drilling, reaming, and finishing operations on both external and internal surfaces. These machines are primarily used in industries like aerospace, automotive, and heavy machinery, where precision and quality are non-negotiable. The choice of a CNC boring mill can significantly impact productivity and the overall quality of manufactured components.

When considering a CNC boring mill for specific manufacturing needs, it is crucial to understand the various applications and types available. For instance, horizontal boring mills are ideal for larger workpieces, offering better stability and precision for complex components. Alternatively, vertical boring mills may be more suitable for smaller components where height and depth are factors. Assessing the type of materials you will be working with can also influence your decision, as different machines cater to varying material properties.

**Tips:** When selecting a CNC boring mill, consider the machine's size and weight capacity to ensure it meets your manufacturing demands. Additionally, pay attention to the control system and software capabilities, which can greatly affect the programming and operational efficiency of the mill. Finally, evaluate service and support options available, as having reliable assistance can significantly reduce downtime and enhance long-term performance.

Top Applications of CNC Boring Mills

This chart displays the percentage distribution of CNC boring mill applications across various industries, highlighting their significance in sectors such as Aerospace, Automotive, Medical Devices, Construction, and Electronics.

Key Factors to Consider When Choosing a CNC Boring Mill

When choosing a CNC boring mill for your manufacturing needs, several key factors should be taken into consideration to ensure optimal performance and efficiency. First, assess the size and type of holes you will be drilling. CNC boring mills come in various configurations and capabilities, so it’s crucial to match the machine’s specifications with your specific requirements. Consider the maximum bore diameter and depth the machine can handle, as well as the materials you will be working with. This will help you determine the necessary spindle speed, feed rate, and tooling options required for your projects.

Another important factor is the level of automation and control features offered by the CNC boring mill. Modern machines equipped with advanced CNC technology provide increased precision, repeatability, and ease of operation. Evaluate the programming capabilities, such as compatibility with CAD/CAM software and user interface design, to ensure a smooth integration into your existing manufacturing processes. Additionally, consider the machine's overall build quality and maintenance requirements, as these can significantly impact long-term reliability and operational costs. Investing time in assessing these factors will ultimately lead to a more informed decision and greater operational success in your manufacturing endeavors.

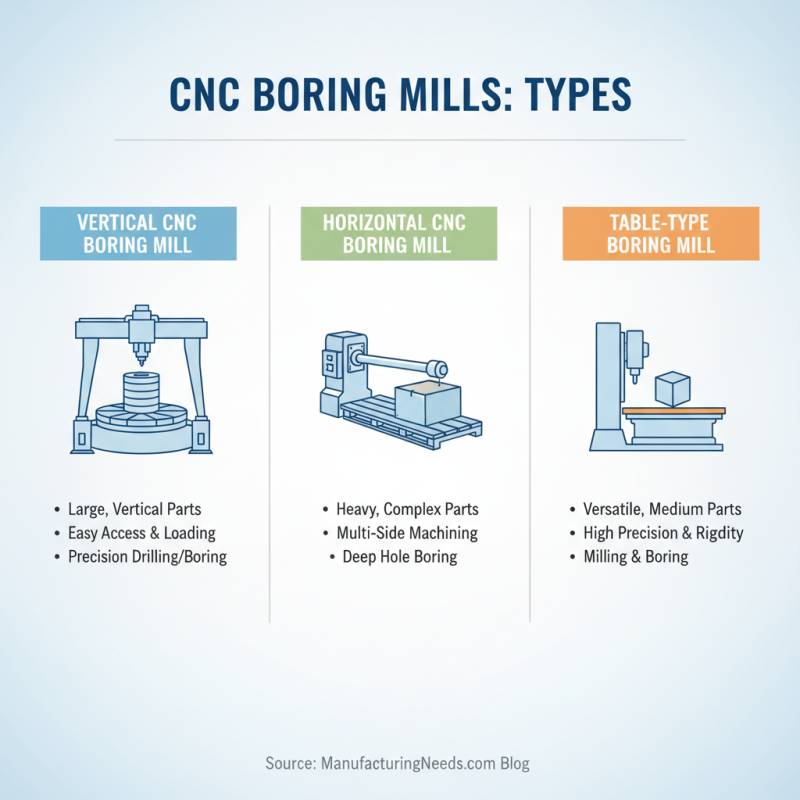

Types of CNC Boring Mills and Their Features

When selecting a CNC boring mill, understanding the different types available is crucial for meeting specific manufacturing needs. The most common types include vertical CNC boring mills, horizontal CNC boring mills, and table type boring mills. Vertical CNC boring mills are prominently used for large, vertically oriented workpieces. They offer the advantage of easy access to the workpiece, making them ideal for operations that require precise drilling and boring at various angles.

On the other hand, horizontal CNC boring mills provide enhanced stability and allow for longer workpieces to be machined effectively. They are particularly suited for heavy components and complex machining tasks, where precision is paramount. Table type boring mills, which combine both vertical and horizontal functions, offer versatility in machining various shapes and sizes. These mills feature a robust table that can support significant weight, allowing for precision in larger projects where multiple setups would be inefficient. Each type of CNC boring mill brings distinct features and benefits tailored to different production requirements, making it essential to assess the specific needs of a manufacturing operation before making a choice.

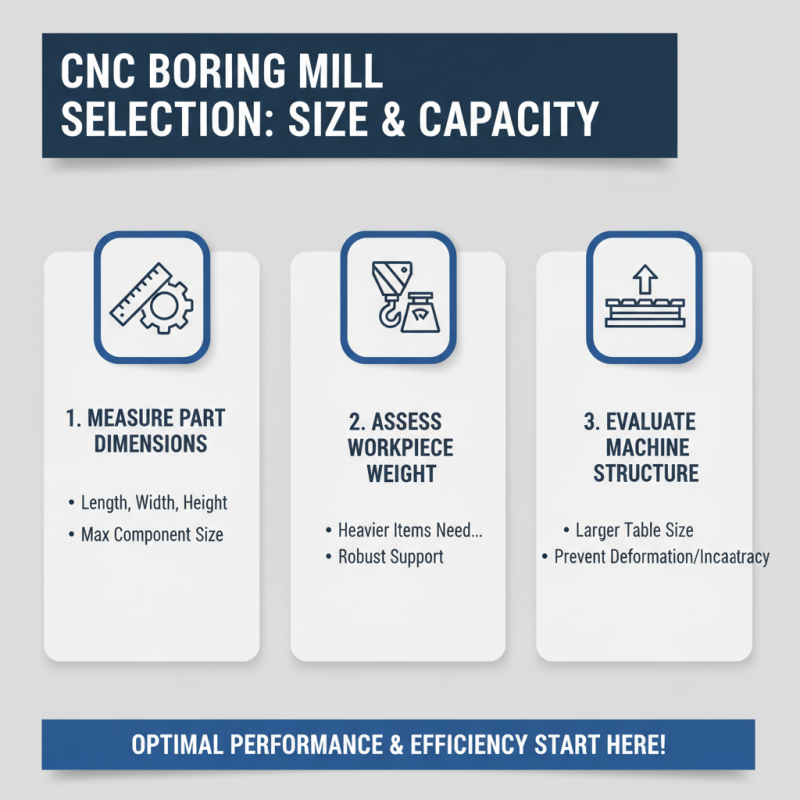

Evaluating the Size and Capacity Requirements for Your Projects

When selecting a CNC boring mill, evaluating the size and capacity requirements for your projects is crucial to ensure optimal performance and efficiency. Different manufacturing tasks require specific dimensions and workloads, meaning that the boring mill must accommodate the size of the components being processed. Begin by measuring the maximum size of parts you plan to work with, including length, width, and height. Additionally, consider the weight of your workpieces, as this will affect the choice of machine. A mill with a larger table and robust support structure will be necessary for heavier and bulkier items to prevent deformation and inaccuracies during operation.

In parallel with size considerations, it's vital to assess the capacity requirements related to your production volume. Analyze the frequency and complexity of the operations you intend to perform. High-volume production might require a CNC boring mill with advanced automation features and faster processing speeds. Conversely, less frequent, highly detailed work may allow for a smaller, more cost-effective option. Ultimately, determining the right balance between size, capacity, and your specific machining needs will enhance both the productivity and quality of your manufacturing processes.

Budgeting and Cost Considerations for CNC Boring Mill Acquisition

When considering the acquisition of a CNC boring mill, budgeting and cost analysis are crucial aspects that can significantly impact your manufacturing operations. According to a report by Grand View Research, the global CNC machine market size is expected to reach approximately $100 billion by 2025, reflecting a robust growth driven by the increasing demand for precision machining across various industries. Therefore, understanding the total cost of ownership (TCO) is essential. TCO includes not only the initial purchase price but also operating costs, maintenance, and potential downtime. Industry data suggests that operating costs can account for up to 70% of the total lifetime cost of a CNC machine.

**Tips:** Before making an investment, calculate your expected return on investment (ROI) based on projected output and operational efficiencies. Consider conducting a cost-benefit analysis to evaluate the long-term savings versus the initial expanse.

Additionally, it's important to factor in the costs associated with training personnel to operate the new machinery efficiently. According to the Fabricators & Manufacturers Association International, skilled labor shortages can further increase operational costs and lead to inefficiencies. Allocating a budget for ongoing training and potential upgrades can ensure that your CNC boring mill remains competitive and aligned with industry standards.

**Tips:** Always maintain a reserve budget for unexpected repairs and improvements. It is advisable to consult with financial experts in the manufacturing sector to refine your budget allocations and prioritize spending effectively.

How to Choose the Right CNC Boring Mill for Your Manufacturing Needs - Budgeting and Cost Considerations for CNC Boring Mill Acquisition

| Parameter | Entry Level | Mid Range | High End |

|---|---|---|---|

| Initial Cost | $50,000 - $80,000 | $80,001 - $150,000 | $150,001+ |

| Maintenance Cost (Annual) | $2,000 - $5,000 | $5,001 - $10,000 | $10,001+ |

| Size (Work Envelope) | Up to 40" x 20" | Up to 60" x 30" | 60" x 40" and above |

| Precision (TIR) | ±0.005" | ±0.001" | ±0.0005" |

| Common Applications | Simple Parts | Medium Complexity Parts | High Complexity Parts |

| Max RPM | 1,500 RPM | 3,000 RPM | 5,000 RPM |

Related Posts

-

Revolutionizing Manufacturing with CNC Boring Mill Innovations at the 138th Canton Fair 2025

-

10 Reasons Why the Best CNC Turning Machine is Essential for Your Business

-

Addressing Common Challenges Associated with Best CNC Equipment in Manufacturing

-

Ultimate Checklist for Selecting the Best CNC Turning Machine for Your Business

-

Solutions for Achieving Precision with the Best CNC Horizontal Boring Mill

-

Ultimate Guide to Sourcing Top Quality CNC Boring Mills: Tips for Global Buyers