How to Choose the Best Ball Screw for Sale in 2026?

As industries evolve, selecting the right ball screw for sale has become increasingly critical. According to a recent market report by Grand View Research, the global ball screw market is expected to reach $4.13 billion by 2026. This growth reflects the importance of precision in motion control applications across various sectors. However, with numerous options available, choosing the best product can be daunting.

Key factors to consider include load capacity, lifespan, and material quality. A ball screw's efficiency affects machinery performance. For example, poor selection can lead to oversized components that increase costs. On the other hand, a well-chosen ball screw can enhance productivity. Many professionals overlook their specific application needs, focusing instead on price alone.

Today’s market offers diverse designs and configurations. Each design caters to unique operational requirements. Industry insiders emphasize the importance of compatibility with existing systems. It's crucial to reflect on the long-term implications of your choice. Proper research can prevent costly mistakes and ensure the right fit. Ultimately, a well-informed decision on a ball screw for sale will support operational excellence.

Understanding Ball Screws: Types and Applications

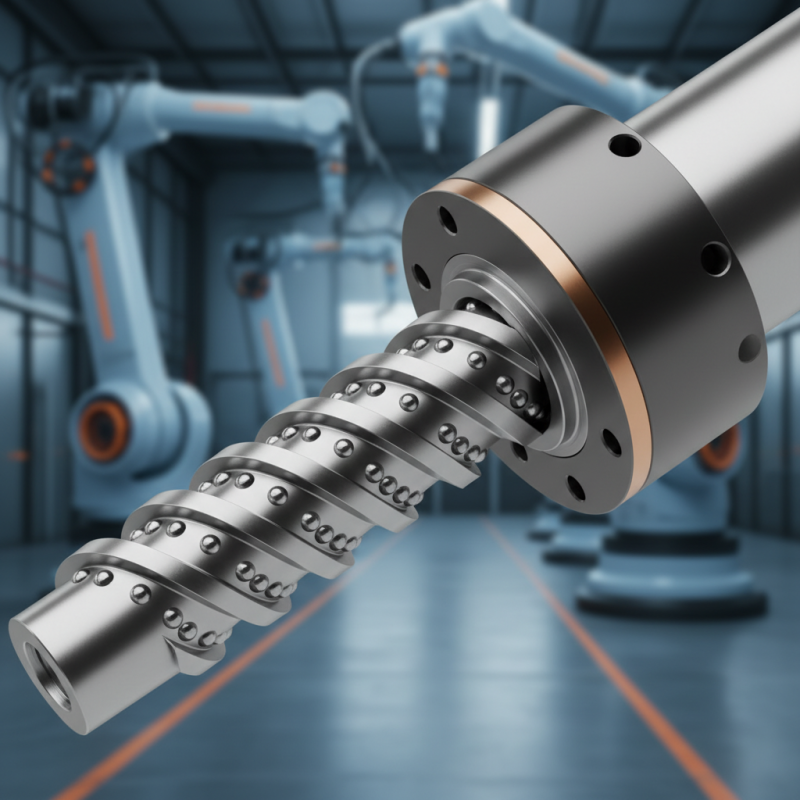

Ball screws are vital components in precision machinery. They convert rotary motion into linear motion. Understanding their types and applications can significantly impact performance.

There are several types of ball screws. Rolled ball screws are common in general applications. They offer decent precision at a low cost. Ground ball screws, on the other hand, provide higher accuracy. They are often used in CNC machines. According to a recent industry report, the global ball screw market is projected to reach $4.54 billion by 2026. This growth highlights the increasing demand for precision machinery.

Applications of ball screws are diverse. They are found in robotics, medical devices, and aerospace. Each application often requires specific design choices. For instance, not all ball screws can handle high loads effectively. Some may wear out quickly, leading to maintenance issues. Engineers must evaluate these factors carefully. Ignoring them can result in operational inefficiencies and costly downtime. It's essential to choose wisely, as the right ball screw can enhance performance significantly.

Key Factors to Consider When Selecting a Ball Screw

When choosing a ball screw, several key factors come into play. Material quality is crucial. Look for durable options that can withstand wear and tear. Steel is often preferred for its strength. However, some applications may benefit from alternatives like stainless steel or plastic composites. Each material has its pros and cons.

Another important aspect is the lead screw design. Different designs cater to various applications. Higher lead values result in faster movement but may sacrifice precision. Consider your specific project needs before making a choice. Ensure it aligns with the operational requirements. This decision can affect overall performance.

Load capacity must also be evaluated. Some ball screws handle heavy loads while others are better suited for lighter applications. Always check the specifications to prevent unexpected failures. There's a learning curve when selecting, so don’t rush through it. The consequences of a poor choice can be costly, both in time and resources.

Material and Mechanical Properties Impacting Performance

When selecting a ball screw, the material and mechanical properties play a crucial role. Steel is a common choice for its high strength. However, it comes with weight. Aluminum offers a lighter alternative but may have lower load capacity. Understanding your application is vital.

Consider the environment where your ball screw will operate. High temperatures can weaken some materials. Corrosion resistance might be crucial in specific industries. A nickel-coated ball screw could be beneficial in humid conditions. But is it overkill? Reflect on your needs.

Mechanical properties also matter significantly. Look at the load rating, precision, and speed capability. A higher load rating can ensure longevity. But this often adds to weight and cost. Is that extra expense justified for your project? Balancing these factors requires careful thought.

Evaluating Manufacturer Reputation and Quality Standards

When selecting a ball screw in 2026, the manufacturer’s reputation is crucial. A trustworthy manufacturer demonstrates consistency in quality and performance. Look for companies with a solid history in the industry. Online reviews can provide insights into customer experiences. Pay attention to common problems or praises. You might notice patterns that inform your decision.

Quality standards play a significant role too. Manufacturers should comply with international quality certifications. These standards ensure reliability and safety in production. However, not all companies highlight their certifications clearly. Some may assume buyers are aware. It’s essential to ask for documentation, proving adherence to standards.

Evaluate materials used in manufacturing. High-quality materials can enhance durability. Yet, it is not always easy to determine material quality. Manufacturers may use technical jargon. Understanding specifications is vital. You may need guidance from technical experts. Trust your instincts, but remain critical. The details matter in the selection process.

Cost Analysis: Budgeting for Ball Screws in 2026

When budgeting for ball screws in 2026, careful cost analysis is essential. Understand your application needs to avoid overspending. Ball screws vary in price based on quality and specifications. High-end screws may offer better performance but can drain your budget quickly.

Tips: Research several suppliers to compare prices. Don’t settle for the first quote. It may take time, but savings can be significant.

Consider the total cost of ownership. Installation and maintenance bring additional expenses. A cheaper ball screw may lead to higher long-term costs. This is a common mistake many make. Evaluate the lifespan and warranty options too.

Doing a thorough cost analysis requires reflection. Ensure that every expense justifies the benefits. Sometimes, it's better to invest more upfront for quality. In the end, quality ball screws can enhance productivity, but they require a mindful budget.