Top Factors to Consider When Choosing a CNC Lathe Machine in 2025

As the manufacturing industry continues to evolve, the importance of selecting the right lathe CNC machine has never been more critical. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2025, driven by the demand for precision and automation across various sectors. This surge underscores the necessity for manufacturers to invest not only in advanced technologies but also in machines that align with their specific operational needs.

Industry expert Dr. Michael Anderson, a leading authority in CNC technology, emphasizes, "Choosing the right lathe CNC machine is essential for optimizing production efficiency and product quality." His insights reflect the current trend where businesses are increasingly making decisions based on factors like machine versatility, precision, and compatibility with existing systems. As we explore the top factors to consider when selecting a lathe CNC machine, it becomes clear that understanding the unique requirements of your operation is vital for harnessing the full potential of this transformative technology.

With advancements in features and capabilities, it's imperative to stay informed about the latest developments and market trends that can impact your choice. By carefully evaluating these elements, manufacturers can ensure they are well-equipped to meet the challenges of 2025 and beyond.

Key Specifications to Evaluate When Selecting a CNC Lathe Machine

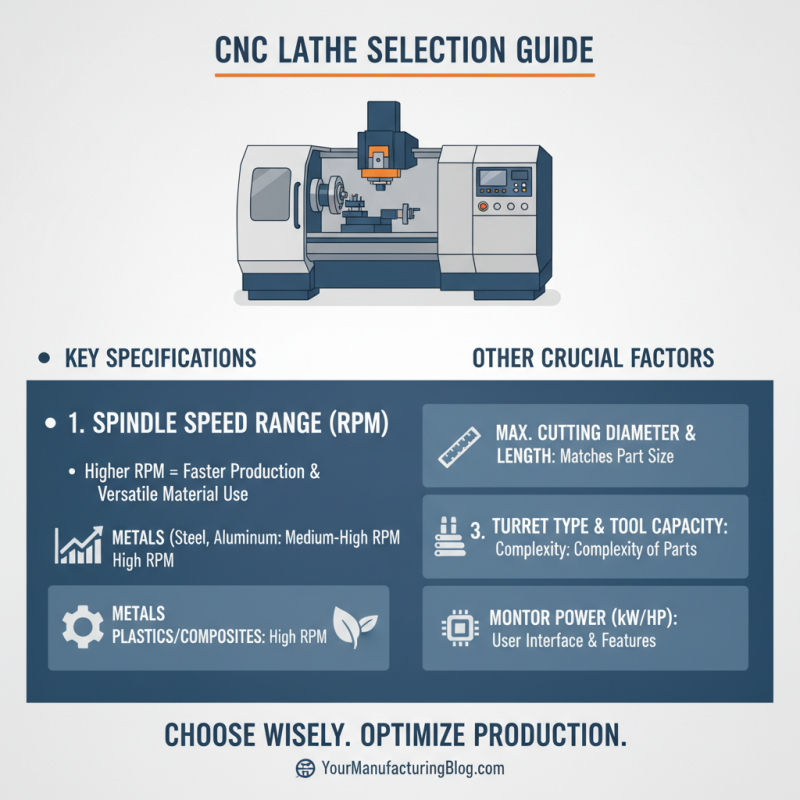

When selecting a CNC lathe machine, understanding the key specifications is crucial to ensuring you make an informed decision that aligns with your manufacturing needs. One of the primary factors to consider is the spindle speed range. A higher spindle speed can significantly improve productivity and allow for a greater variety of materials to be machined effectively. Knowing the optimal speed for the materials you typically work with can guide you in choosing a machine that meets those specifications.

Another vital specification is the travel distance or capacity of the machine. This refers to the maximum length and diameter of the workpieces that the CNC lathe can handle. Depending on your projects, you’ll want to assess whether the machine can accommodate your largest parts without compromising machining precision. Additionally, consider the power of the spindle motor, as this will affect the machine's cutting capabilities and overall efficiency, especially when dealing with tough materials.

Lastly, it’s essential to evaluate the control system of the CNC lathe. A user-friendly interface, along with advanced programming options, can greatly enhance productivity and reduce training time for operators. Look for machines that support modern communication standards and integrate well with existing workflows to streamline your operations. By focusing on these specifications, you can ensure that your choice of CNC lathe machine will effectively support your production needs in the evolving manufacturing landscape of 2025.

Understanding the Types of CNC Lathe Machines Available in 2025

In 2025, the CNC lathe machine landscape continues to evolve, offering various types tailored to meet diverse manufacturing requirements. The primary categories include CNC turning centers, Swiss-type CNC lathes, and vertical CNC lathes. CNC turning centers are widely recognized for their ability to perform multiple operations, combining turning, milling, and drilling processes into a single setup, which enhances efficiency. According to a report by MarketsandMarkets, the CNC lathe market is projected to grow at a CAGR of 6.3% from 2023 to 2028, driven largely by advancements in multi-tasking capabilities.

Swiss-type CNC lathes, on the other hand, stand out for their precision and ability to handle complex part geometries, making them ideal for industries such as medical device manufacturing and high-precision engineering. This type of machine offers a unique sliding headstock mechanism, allowing for tighter tolerances and reduced material waste. Industrial analysts indicate that the demand for Swiss-type lathes will witness a significant increase as manufacturers strive for smaller and more intricate components, especially as the market adjusts to the growing trend of miniaturization in technology.

Lastly, vertical CNC lathes are gaining popularity due to their ability to manage larger workpieces with reduced floor space and enhanced chip control. Their design is ideal for heavy-duty machining operations, making them a preferred choice for industries dealing with large castings or forgings. With the continuous increase in manufacturing automation, adopting vertical CNC lathe technology is expected to rise, aligning with the projected growth of the CNC machine tools market, estimated to surpass USD 150 billion by 2027, as per a recent industry forecast.

Top Factors to Consider When Choosing a CNC Lathe Machine in 2025

| Feature | Description | Importance Level |

|---|---|---|

| Machine Type | CNC turning center, CNC turret lathe, etc. | High |

| Size and Capacity | Max diameter and length of parts the machine can handle | High |

| Power Requirements | Voltage and current ratings | Medium |

| Control System | Fanuc, Siemens, etc. | High |

| Automation Features | Ability to integrate with automation solutions | Medium |

| Budget | Initial purchase cost and long-term maintenance costs | High |

| Brand Reputation | Reviews and reliability of the manufacturer | Medium |

| Customer Support | Availability and quality of after-sales service | High |

Influence of Material Compatibility on CNC Lathe Choice

When selecting a CNC lathe machine in 2025, material compatibility stands out as a critical factor that can significantly influence the efficiency and outcome of machining operations. The choice of materials directly impacts the selection of cutting tools and the parameters under which they operate. According to a report by the International Manufacturing Technology Show (IMTS) 2023, nearly 70% of manufacturers now prioritize material compatibility in their CNC machine selection process, highlighting its importance in ensuring optimal machining performance.

Advancements in material technology have led to the emergence of specialized alloys and composites that require specific machining techniques. For instance, titanium and carbon fiber, while increasingly popular, necessitate CNC lathes with higher torque capabilities and advanced cooling systems to prevent tool wear and maintain precision. A study conducted by the Metalworking Trends Institute found that mismatches in material and machine capabilities can result in production inefficiencies, with a potential increase in production costs by up to 15%. This emphasizes the need for manufacturers to carefully evaluate the materials they intend to work with, ensuring their CNC lathe machines are equipped to handle the desired materials effectively.

Additionally, as sustainability becomes a focal point in manufacturing, the compatibility of CNC lathes with recyclable materials and eco-friendly cutting processes is gaining traction. The Global Manufacturing Sustainability Report indicated that 58% of firms are now actively seeking CNC machines that support environmentally responsible practices. This trend will likely reshape the market, pushing manufacturers to select CNC lathes that not only meet their material requirements but also align with sustainable manufacturing initiatives, thereby influencing the CNC lathe choices to come.

Assessing Automation Features for Increased Efficiency

When choosing a CNC lathe machine in 2025, assessing automation features is crucial for maximizing efficiency and productivity in manufacturing operations. Automation technologies have evolved significantly, enabling CNC lathes to perform complex tasks with minimal human intervention. Features such as automatic tool changers, adaptive machining, and enhanced programming capabilities allow for faster turnaround times and reduced setup periods, ultimately leading to improved production efficiency. Users should evaluate how these automation features can integrate into their existing workflows, ensuring smooth transitions and minimal disruption during implementation.

Additionally, consider the machine's ability to accommodate advanced monitoring and data analytics tools. Machines equipped with real-time monitoring systems can provide insights into performance metrics and machine health, allowing for predictive maintenance and timely interventions. This not only increases the lifespan of the CNC lathe but also reduces downtime, making it an essential feature for manufacturers seeking sustained operational efficiency. Furthermore, the ability to program and adjust operations remotely through user-friendly interfaces can significantly enhance workflow flexibility, empowering operators to respond quickly to changing production demands.

Top Factors in Choosing a CNC Lathe Machine for 2025

The chart above illustrates the key factors to consider when selecting a CNC lathe machine in 2025, ranked by their importance. Automation features are deemed the most critical for enhancing efficiency, followed by cutting accuracy and user-friendliness.

Importance of After-Sales Support and Service in Purchase Decisions

When investing in a CNC lathe machine in 2025, one critical aspect that should not be overlooked is the importance of after-sales support and service. The complexity of CNC machinery requires not only a significant initial financial investment but also ongoing maintenance and potential repairs. A robust after-sales support system ensures that operators can maximize machine uptime, thereby enhancing productivity and efficiency in operations. Companies that offer comprehensive service packages often include training, technical support, and quick response times, which can be invaluable in ensuring that production processes continue without significant interruptions.

Furthermore, the quality of after-sales service can significantly influence the overall user experience. A manufacturer that prioritizes customer support is likely to cultivate long-lasting relationships and loyalty among its clients. This can be particularly crucial for businesses that rely on CNC lathes for precision work, where even minor downtime can lead to substantial financial losses. Before making a purchase, it is essential to evaluate the support services provided, including the availability of spare parts, training resources, and expert advice, as this can ultimately impact the operational efficiency and profitability of a business in a competitive market.

Related Posts

-

Exploring the Future of Horizontal Milling Machines at the 138th Canton Fair 2025: Industry Insights and Trends

-

China's Best CNC Vertical Machining Center for Global Buyers Trust in Quality and Innovation

-

Ultimate Guide to Maximizing Efficiency with CNC Turning Centers

-

10 Essential Tips for Choosing the Right CNC Machining Center

-

Revolutionizing Precision Engineering with CNC Horizontal Boring Mills

-

Unveiling the Technical Specifications of the Best Vertical CNC Machines for Global Buyers