How to Choose the Right Horizontal Machining Center for Your Needs?

Choosing the right horizontal machining center can be challenging. With many options available, making a decision requires careful consideration. A horizontal machining center is vital for improving productivity and precision in manufacturing processes.

When evaluating different models, focus on your specific needs. Consider factors such as size, capabilities, and budget. You want a machine that fits your shop’s layout and workload. Take the time to review specifications and features. Not all machines are created equal, and what works for one shop may not work for another.

Reflect on your long-term goals. Investing in a horizontal machining center is significant. Ensure it aligns with your production needs now and in the future. Don't rush the process. A well-chosen machine will enhance efficiency, while a hasty choice may lead to regrets.

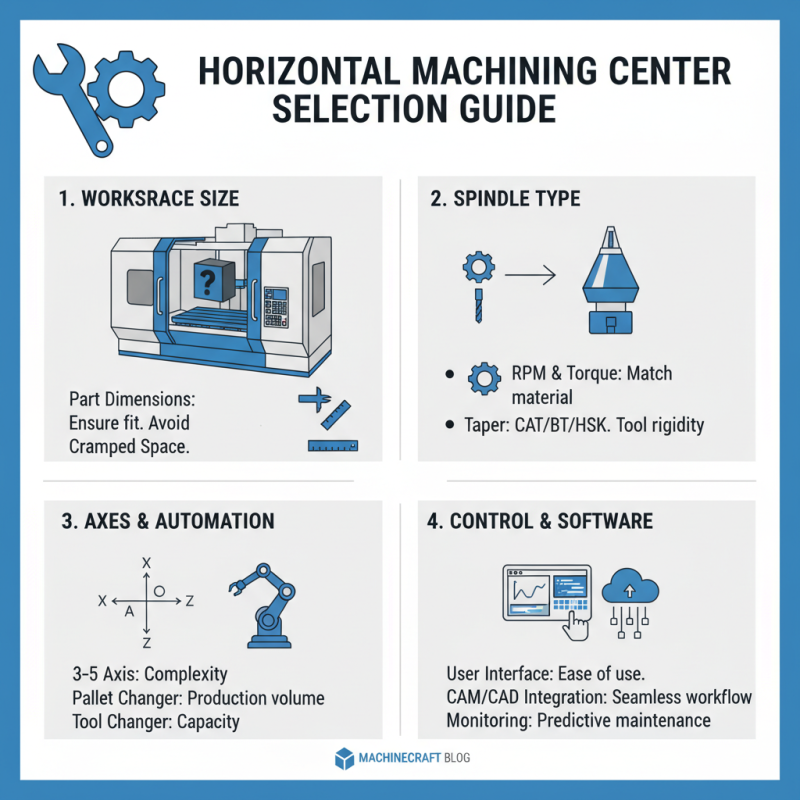

Factors to Consider When Selecting a Horizontal Machining Center

When selecting a horizontal machining center, several factors come into play. The size of the workspace is paramount. Consider the dimensions of your parts. Will they fit comfortably? A cramped workspace can lead to inefficiencies. Ensure that the center can accommodate your largest components with ease.

Another critical aspect is the machine's spindle speed and power. These specifications directly affect productivity and material compatibility. For heavy-duty materials, a powerful spindle is essential. Assess the types of materials you typically work with, and choose a machine that meets those needs.

Lastly, think about automation. Automation features can significantly enhance efficiency. However, they often come with complexities. Some users find automation confusing at first. It’s crucial to weigh the benefits against the learning curve. Investing in training could be necessary to maximize your machine’s potential.

Understanding the Different Types of Horizontal Machining Centers

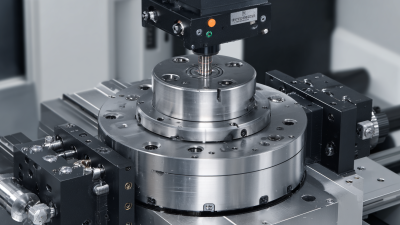

When choosing a horizontal machining center, it's essential to understand the different types available. Horizontal machining centers can be classified into several categories based on their design and functionality. The two most common types are the pallet changer and the twin spindle models. Each serves different manufacturing needs and has its benefits.

Pallet changers offer fast production changes, which is vital for reducing downtime. They allow for quick setup and tool changes, making them ideal for batch production.

On the other hand, twin spindle machines provide enhanced efficiency. They can cut materials simultaneously, boosting productivity for large orders.

Choosing the right type is challenging. It requires careful consideration of your specific requirements. Some centers may lack the versatility you need. Always evaluate what tasks you perform most often. Understanding your priorities will help you make a more informed decision.

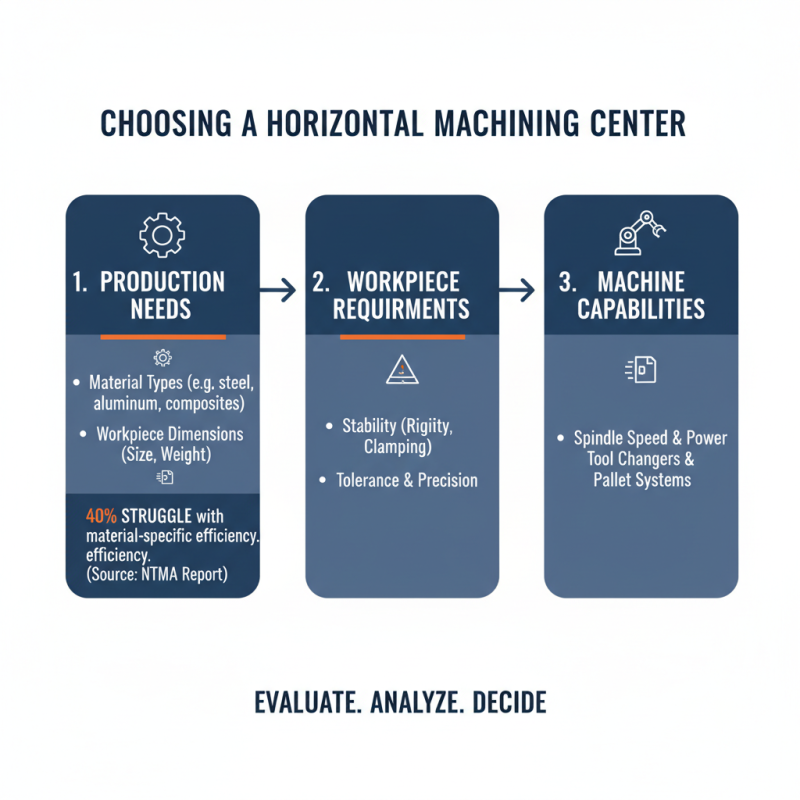

Evaluating Your Production Needs and Workpiece Requirements

When choosing a horizontal machining center, evaluating production needs is essential. Consider the types of materials you work with. According to a report by the National Tooling and Machining Association, nearly 40% of manufacturers struggle to find machines that handle specific materials efficiently. Identify the workpiece dimensions and stability requirements before making a decision.

Tips: Assess the weight capacity of the machining center. Ensure it matches your heaviest workpieces. Underestimating this can lead to costly mistakes.

Next, think about the complexity of your projects. If you process intricate parts, select a machine with advanced features. Data from industry analysis shows that 55% of shops enhance productivity by using multi-axis capabilities. Reflect on how often you need to switch setups. A flexible machine can save time and increase efficiency.

Tips: Evaluate available tooling options. Having the right tools can significantly impact productivity. Don't forget to factor in maintenance needs, too. Regular upkeep is essential for longevity.

Assessing Budget and Cost-Effectiveness for Machining Centers

When selecting a horizontal machining center, budget is a critical factor. Assess your financial limits honestly. It's easy to get swayed by high-end models. But remember, a higher price doesn't always guarantee better results. Analyze the total cost, including installation and maintenance. Sometimes, a less expensive model meets your needs perfectly.

Cost-effectiveness is not just about the initial purchase price. Consider long-term operation costs. Energy efficiency can significantly affect your overall budget. Look for centers that offer good reliability to minimize downtime. A machining center might seem budget-friendly, but repair costs can quickly add up.

Lastly, think about the specific features you need. It’s tempting to opt for advanced technology, but will you use it? Focus on functionality rather than flashy options. Identify what truly enhances your production. This approach will help you avoid overpaying for unnecessary features. Finding the right balance between budget and capability is crucial for optimal investment.

How to Choose the Right Horizontal Machining Center for Your Needs?

| Model | Price (USD) | Table Size (mm) | Spindle Speed (RPM) | Power (kW) | Tool Capacity | Weight (kg) |

|---|---|---|---|---|---|---|

| Model A | $80,000 | 800 x 500 | 10,000 | 22 | 24 | 3,500 |

| Model B | $95,000 | 1000 x 600 | 12,000 | 30 | 30 | 4,000 |

| Model C | $120,000 | 1200 x 800 | 15,000 | 37 | 40 | 5,000 |

| Model D | $140,000 | 1500 x 1000 | 18,000 | 45 | 50 | 6,500 |

Key Features and Specifications to Look for in a Machining Center

When selecting a horizontal machining center, several key features and specifications should guide your choice. The size of the work envelope is critical. It determines the maximum dimensions for your parts. If you often machine larger components, ensure the center meets those needs. Pay attention to spindle speed and power, as they affect productivity. A higher spindle speed often leads to faster machining but may require more robust tooling.

Equally important is the tooling system. Look for flexibility in tool holders and compatibility with various tools. This versatility allows you to adapt to different projects without significant downtime. Additionally, consider the control system. A user-friendly interface can minimize errors during operation. Some systems offer advanced features like automated processes, which can be very beneficial.

Yet, don’t overlook maintenance considerations. Regular upkeep is essential for optimal performance but can be time-consuming. Assess the availability of service and support in your area. Sometimes, what seems to be an affordable option may lead to unexpected costs later. Balancing initial investment against long-term reliability is a vital part of the decision-making process.

Related Posts

-

Unlocking Efficiency: The Rise of Horizontal Machining Centers in Precision Manufacturing

-

Exploring Top Alternatives to the Best Vertical CNC Machine for Global Buyers

-

Mastering Precision: A Step-by-Step Guide to Operating a 5 Axis Milling Machine

-

How to Select the Right Vertical Machining Center for Your Manufacturing Needs

-

Exploring the Future of Manufacturing Through Advanced CNC Machine Tools

-

Revolutionizing Precision Engineering with CNC Horizontal Boring Mills