Revolutionizing Manufacturing with CNC Boring Mill Innovations at the 138th Canton Fair 2025

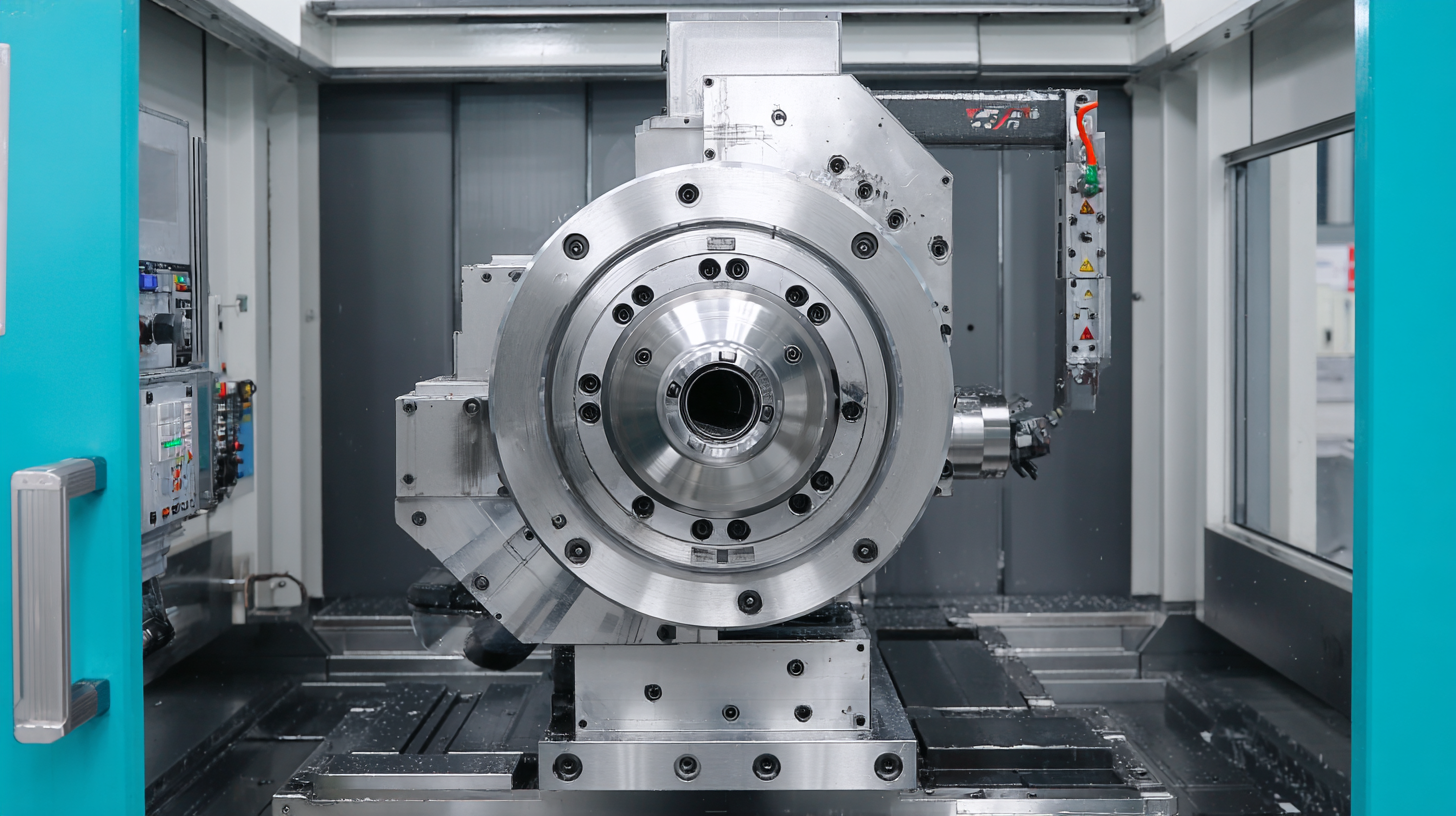

As industries continue to embrace technological advancements, the CNC boring mill emerges as a pivotal innovation in the realm of manufacturing. The 138th Canton Fair in 2025 serves as a significant platform to showcase these groundbreaking developments. This event not only highlights the latest machinery and equipment but also underscores how CNC boring mills are revolutionizing production processes across various sectors. With their precision, efficiency, and versatility, CNC boring mills enable manufacturers to achieve heightened accuracy and reduced operational costs. The Canton Fair provides an exceptional opportunity for industry professionals to explore these innovations, engage with leading manufacturers, and discuss the future of CNC technology in enhancing production capabilities. As we delve into the insights and trends presented at this prestigious event, it becomes clear that the impact of CNC boring mills will play a crucial role in shaping the future of manufacturing.

CNC Boring Mill Innovations: Transforming the Landscape of Manufacturing

The realm of manufacturing is on the brink of a significant transformation, largely fueled by the advancements in CNC boring mill technologies showcased at the 138th Canton Fair in 2025. These innovations are not only reshaping traditional manufacturing processes but also enhancing precision and efficiency. CNC boring mills enable manufacturers to achieve tighter tolerances and superior finishes, making them indispensable in industries ranging from aerospace to automotive.

To fully leverage these innovations, manufacturers should consider investing in training programs for their workforce. Understanding the intricacies of CNC technology is crucial for operators to maximize productivity. Additionally, integrating IoT capabilities into CNC boring mills can provide real-time data analytics, allowing for predictive maintenance and minimizing downtime.

Tip: Regularly update software and firmware for CNC machines to ensure compatibility with the latest technological advancements. This practice not only enhances performance but also extends the longevity of equipment, ensuring that your investment continues to yield returns in a rapidly evolving marketplace.

CNC Boring Mill Innovations: Transforming the Landscape of Manufacturing

Key Technological Advancements in CNC Boring Mill Design and Functionality

The CNC boring mill market is experiencing significant growth driven by recent technological advancements in design and functionality. By 2032, the expanding applications of CNC boring mills are expected to cater to diverse industries, including metal manufacturing, mining, and cement production. The market size for CNC boring mills is projected to reach substantial figures, thanks to the rise in demand for precision machining and automation.

The integration of innovative materials and streamlined processes enhances efficiency and reduces operational costs, making CNC boring mills an attractive investment for manufacturers.

In parallel, the market for mill linings such as metal, rubber, and composite materials is also evolving. The mill lining market is expected to grow from $120 million in 2022 to $190 million by 2030, with a compound annual growth rate (CAGR) of 7.3% from 2024 to 2030. This growth is fueled by the increasing need for durable and high-performance linings in various industrial applications.

Additionally, the kraft liner market is anticipated to witness considerable expansion, reaching $32.17 billion by 2031, further indicating a robust trend towards technological innovations that improve manufacturing capabilities across industries.

Enhancing Production Efficiency: The Impact of CNC Boring Mills on Manufacturing

The impact of CNC boring mills on manufacturing efficiency cannot be overstated. According to a recent report by Market Research Future, the global CNC machining market is expected to grow at a CAGR of 7.8% from 2021 to 2028, driven largely by advancements in CNC technologies. CNC boring mills, specifically, enhance precision in machining operations, enabling manufacturers to achieve tighter tolerances and improved surface finishes, which are critical for competitive advantage in sectors like aerospace and automotive.

Moreover, the adoption of CNC boring mills significantly reduces production time, a crucial factor in today's fast-paced market. Studies indicate that manufacturers utilizing CNC technology can increase their productivity by up to 40% compared to traditional machining methods. This efficiency not only leads to cost savings but also allows companies to respond more swiftly to customer demands. As seen at the 138th Canton Fair, innovations in CNC boring mills are setting new benchmarks for performance and reliability, compelling manufacturers to rethink their production strategies and embrace these cutting-edge solutions.

Sustainability in Manufacturing: Eco-friendly Practices with CNC Boring Technology

At the 138th Canton Fair 2025, the spotlight on CNC boring mill innovations showcases the manufacturing sector’s commitment to sustainability. These advancements in boring technology are not just enhancing production efficiency but are also paving the way for eco-friendly practices. Manufacturers are increasingly adopting CNC systems that minimize waste, reduce energy consumption, and utilize recyclable materials, thereby lowering their overall ecological footprint.

CNC boring mills are revolutionizing traditional manufacturing processes by integrating smart technology that optimizes resource usage. For instance, adaptive control systems adjust cutting parameters in real time to ensure minimal material wastage. Additionally, the development of biodegradable coolants and lubricants is a significant stride towards reducing harmful emissions associated with conventional manufacturing practices. This fusion of innovation and sustainability is setting a benchmark for future manufacturing endeavors, reflecting an industry-wide shift towards environmentally responsible operations that align with global sustainability goals.

Networking Opportunities at the 138th Canton Fair: Connecting Innovators and Manufacturers

The 138th Canton Fair 2025 is set to be a pivotal event for industry professionals eager to explore the latest advancements in CNC boring mill technology. This year's fair emphasizes not just innovation but also the importance of networking among manufacturers and innovators. According to a recent market analysis by Research and Markets, the global CNC machine market is anticipated to grow at a CAGR of around 6.3% from 2021 to 2026, highlighting the importance of collaboration in fostering industry growth and technological advancements.

Networking opportunities at the Canton Fair facilitate valuable connections that drive progress in the manufacturing sector. With over 25,000 exhibitors and thousands of international buyers expected, attendees will have the chance to engage in meaningful discussions, share insights, and collaborate on futuristic projects.

The significance of such connections is underscored by data from the World Economic Forum, which suggests that up to 70% of successful manufacturing innovations stem from strategic partnerships and collaborations. The event is not just about showcasing products; it is about cultivating relationships that can lead to groundbreaking developments in manufacturing practices.

Related Posts

-

7 Key Advantages of Using CNC Boring Mills for Precision Manufacturing

-

Exploring Top Alternatives to the Best Vertical CNC Machine for Global Buyers

-

Unveiling the Technical Specifications of the Best Vertical CNC Machines for Global Buyers

-

China's Best CNC Vertical Machining Center for Global Buyers Trust in Quality and Innovation

-

7 Key Features That Make the Best Vertical Machining Centers Stand Out in 2023

-

Top Strategies for Maximizing Efficiency with Large Milling Machines