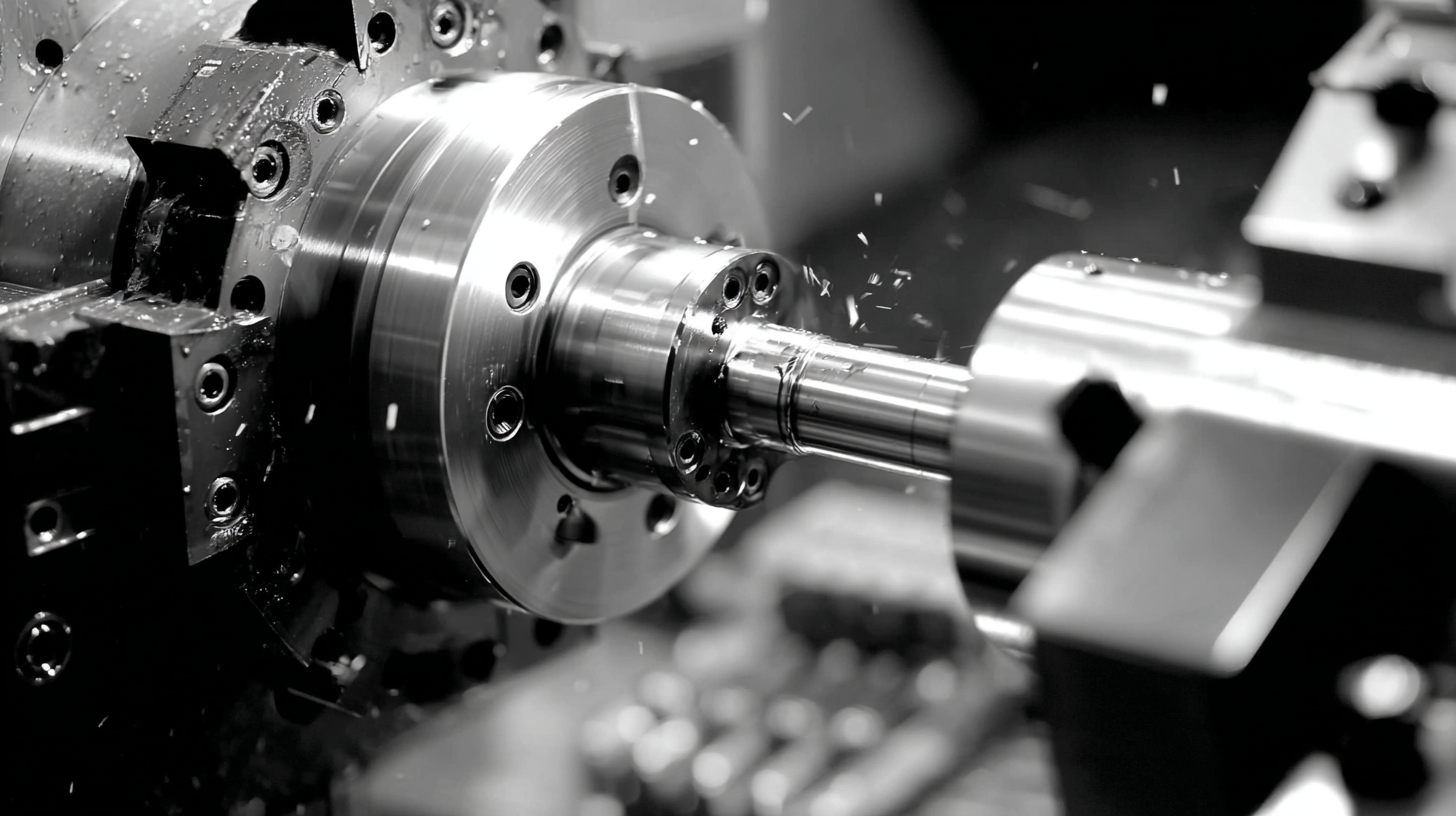

Why CNC Turning Machines Are Essential for Modern Manufacturing Efficiency

In today’s fast-paced manufacturing landscape, the role of precision and efficiency cannot be overstated, making the cnc turning machine an indispensable tool for modern production processes. According to a report by MarketsandMarkets, the CNC machine market is projected to reach USD 100 billion by 2025, driven by the increasing demand for automation and the rising need for high precision manufacturing. CNC turning machines, with their ability to produce complex geometries and tight tolerances with minimal human intervention, are a key contributor to this trend.

They enhance operational efficiency by reducing cycle times and waste, ultimately leading to higher productivity rates. As industries increasingly adopt smart manufacturing techniques, investing in advanced cnc turning solutions is critical for staying competitive and meeting the evolving demands of the market.

The Role of CNC Turning Machines in Streamlining Production Processes

CNC turning machines have emerged as a critical component in modern manufacturing, significantly enhancing the efficiency of production processes. By automating the machining of complex parts, these machines reduce human error and increase precision. In an era where speed and accuracy are paramount, CNC turning allows manufacturers to produce high-quality components at a fraction of the time required by traditional methods. The digital control offered by CNC technology enables operators to execute multiple operations, from cutting to finishing, in a single machining cycle, streamlining the entire production workflow.

The integration of CNC turning machines into manufacturing operations also facilitates greater flexibility in production. Manufacturers can quickly adjust to changing demands by reprogramming the machines for new designs without the need for extensive retooling. This adaptability is crucial in industries where customization and rapid turnaround times are essential. Furthermore, the data generated by CNC machines provides valuable insights into the production process, allowing for ongoing improvements and optimized performance. As a result, businesses that leverage CNC turning technology can achieve a competitive edge in the fast-paced manufacturing landscape.

Why CNC Turning Machines Are Essential for Modern Manufacturing Efficiency

| Feature | Description | Impact on Efficiency |

|---|---|---|

| Automation | CNC turning machines automate the machining process, reducing the need for skilled labor. | Increases production speed and consistency. |

| Precision | Offers high precision in machining with tight tolerances. | Reduces waste and rework costs. |

| Flexibility | Can be programmed for various tasks and materials. | Allows manufacturers to adapt quickly to changes in design. |

| Reduced Lead Time | Shortens the time needed to produce components. | Enhances customer satisfaction with faster delivery. |

| Quality Control | Integrates quality inspection in the production process. | Improves overall product quality and reliability. |

Key Statistical Insights on CNC Technology's Impact on Manufacturing Yield

CNC turning machines play a pivotal role in enhancing manufacturing efficiency, particularly in the context of Industry 4.0. Recent studies show that integrating CNC technology can improve production yields by up to 30%, a crucial statistic for manufacturers aiming to stay competitive in rapidly evolving markets. As industries like automotive and electronics approach full digital adoption, the efficiency gains from CNC turning machinery become increasingly significant, allowing for both precision and speed in production processes.

CNC turning machines play a pivotal role in enhancing manufacturing efficiency, particularly in the context of Industry 4.0. Recent studies show that integrating CNC technology can improve production yields by up to 30%, a crucial statistic for manufacturers aiming to stay competitive in rapidly evolving markets. As industries like automotive and electronics approach full digital adoption, the efficiency gains from CNC turning machinery become increasingly significant, allowing for both precision and speed in production processes.

Manufacturers must recognize the importance of optimizing their use of CNC machines to fully capture the advantages of digital transformations. According to reports, companies that effectively implement CNC technology can experience a reduction in waste and lead times, contributing to overall cost savings. Furthermore, with advancements in AI and machine learning, CNC turning machines are becoming smarter, providing valuable data for continuous improvement.

Tips for Manufacturers:

1. Invest in training programs for staff to maximize the potential of CNC technology.

2. Regularly assess machine performance with key metrics to identify areas for improvement.

3. Stay updated on Industry 4.0 trends to ensure your operations remain cutting-edge and efficient.

Cost-Benefit Analysis of Implementing CNC Turning in Modern Facilities

In today's manufacturing landscape, the implementation of CNC turning machines presents a compelling cost-benefit scenario. According to a report by MarketsandMarkets, the global CNC machine market is projected to grow from $63.4 billion in 2022 to $117.6 billion by 2028, reflecting a robust compound annual growth rate (CAGR) of 10.5%. This growth highlights how companies increasingly recognize the efficiency and precision that CNC turning technology offers, ultimately leading to cost savings through reduced waste and enhanced production speed.

A study from the Federal Manufacturing Partnership revealed that manufacturers can achieve up to a 30% decrease in operational costs by integrating CNC turning machines into their workflow. This reduction primarily stems from improved machining accuracy, which lowers the rate of rework and scrap material. Additionally, the ability to automate complex processes means that facilities can save on labor costs, with some businesses noting a productivity increase of 25% or more. Such data underscores the vital role CNC turning machines play in boosting both productivity and profitability in modern manufacturing environments.

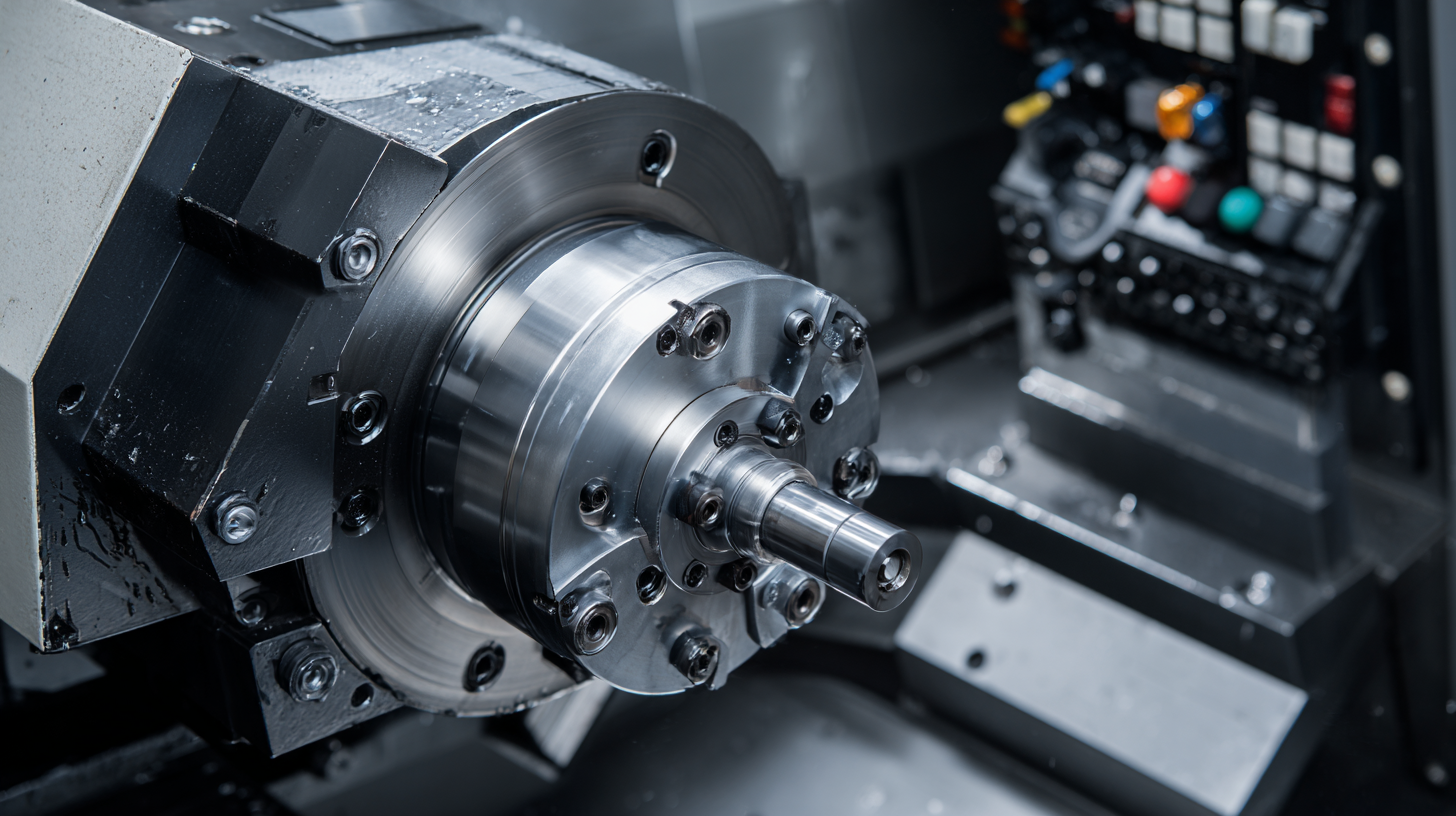

Enhancing Precision: How CNC Turning Machines Improve Product Quality

CNC turning machines play a pivotal role in enhancing precision within the manufacturing sector. These advanced tools utilize computer numerical control to automate the machining processes, allowing for highly accurate production of components. With the ability to produce parts with tolerances as tight as a few microns, CNC turning machines ensure that every piece meets strict quality standards. The ability to replicate exact specifications consistently helps manufacturers reduce waste and minimize error, thus improving overall product quality.

Moreover, CNC turning machines are equipped with sophisticated software that enables detailed monitoring and adjustment of the machining process in real-time. This capability allows manufacturers to detect discrepancies early and make necessary adjustments swiftly, preventing defects before they occur. By integrating this technology, companies can achieve a higher level of precision than traditional machining methods, resulting in components that not only perform better but also have a longer lifespan. As manufacturing continues to evolve, the precision offered by CNC turning machines will remain essential to meeting the demands for high-quality products in a competitive market.

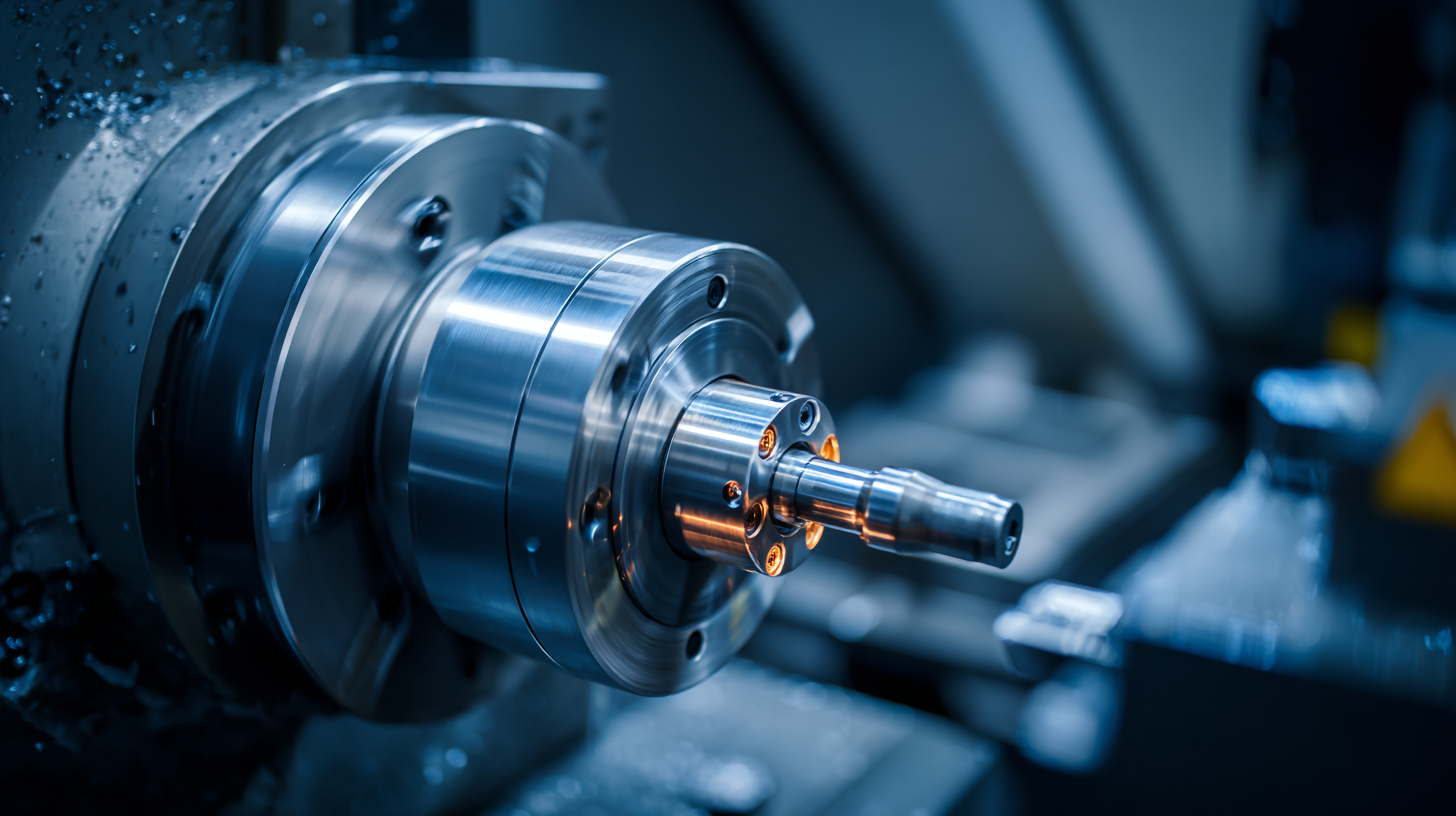

Future Trends: Innovations in CNC Turning Machines for Increased Efficiency

The future of CNC turning machines is being shaped by innovative advancements that focus on enhancing efficiency and precision in manufacturing processes. Artificial intelligence is at the forefront of this transformation, enabling CNC systems to autonomously optimize machining operations. This integration not only reduces human errors but also streamlines workflows, significantly minimizing production downtime while maximizing throughput. As a result, manufacturers are witnessing substantial improvements in overall productivity, allowing them to meet the rising demands of competitive markets.

Moreover, the Equipment-as-a-Service (EaaS) model is gaining traction in the machinery sector, propelled by digitalization trends. This shift encourages businesses to adopt CNC technologies without the burden of significant upfront capital investments. Instead, companies can access advanced machinery on a subscription basis, allowing for flexibility and rapid upgrades that keep pace with technological advancements. As the CNC controller market is projected to grow significantly, the emphasis on incorporating AI and digital solutions indicates a clear trajectory towards smarter, more efficient manufacturing practices.

Manufacturing Efficiency Improvements Through CNC Turning Machines

Related Posts

-

10 Reasons Why the Best CNC Turning Machine is Essential for Your Business

-

Ultimate Checklist for Selecting the Best CNC Turning Machine for Your Business

-

Discovering the Best Alternatives to CNC Machining Centers for Global Buyers

-

Exploring CNC Turning Center Applications: Innovative Examples Across Industries

-

How to Select the Right Vertical Machining Center for Your Manufacturing Needs

-

Ultimate Guide to Maximizing Efficiency with CNC Turning Centers