Unlocking Efficiency: The Rise of Horizontal Machining Centers in Precision Manufacturing

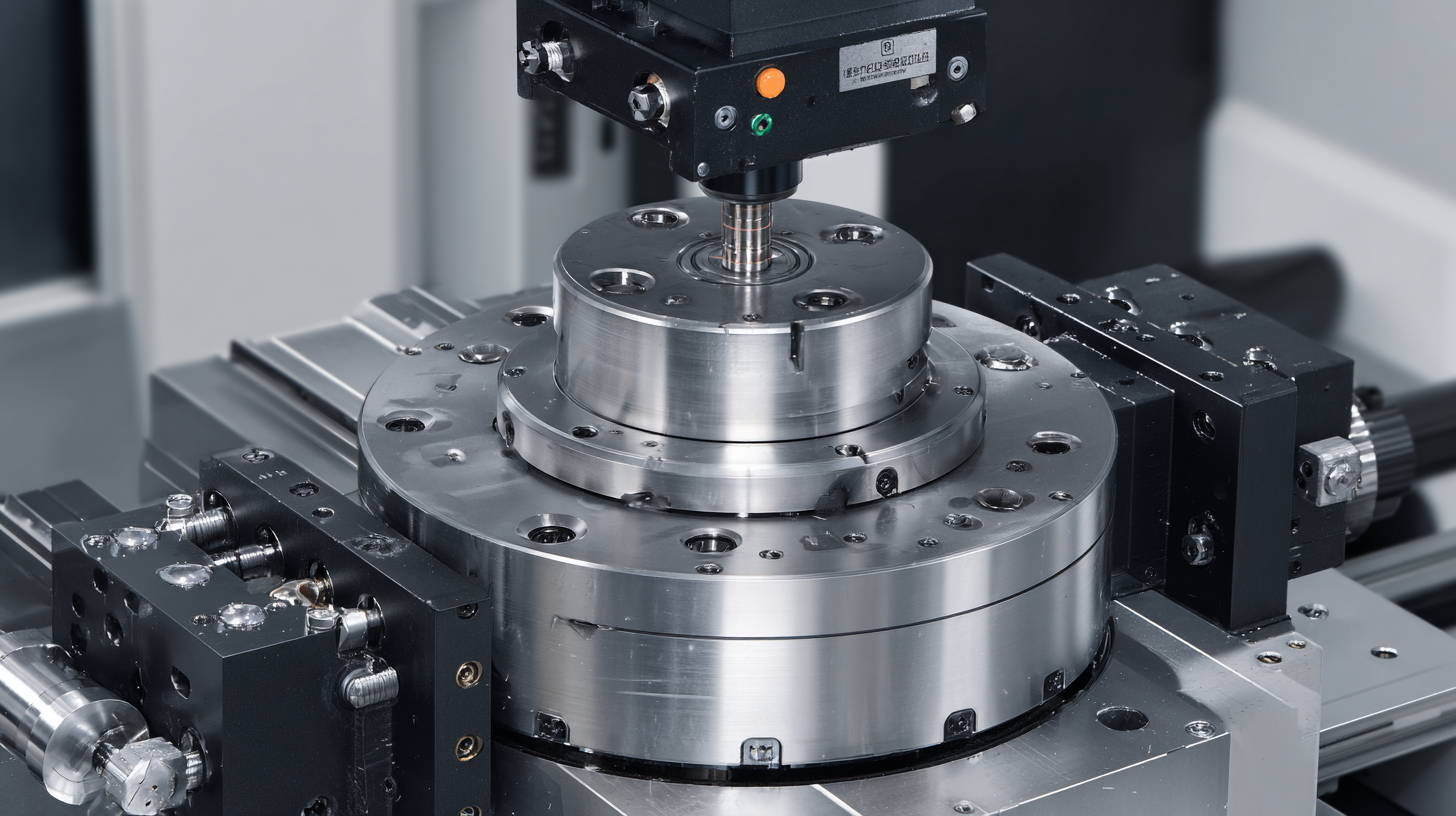

In the realm of precision manufacturing, the evolution of technology has paved the way for advanced machinery that drastically enhances productivity and efficiency. One of the standout innovations in this field is the horizontal machining center, a versatile machine that has transformed the way manufacturers approach complex machining tasks. Unlike traditional vertical machining centers, horizontal machining centers offer a range of benefits, including improved accessibility, better chip removal, and increased stability during multi-axis operations. As industries demand more precision and faster turnaround times, the adoption of horizontal machining centers has surged, enabling manufacturers to optimize their workflows and meet the high standards of modern production.

This article aims to explore the key functionalities, advantages, and implications of integrating horizontal machining centers into manufacturing practices, shedding light on how they unlock unprecedented levels of efficiency in precision manufacturing.

The Evolution of Machining Technologies: From Vertical to Horizontal Centers

The evolution of machining technologies has seen a significant shift from traditional vertical machining centers to the more advanced horizontal machining centers. Horizontal machining centers (HMCs) are gaining traction in precision manufacturing due to their ability to enhance productivity and reduce cycle times. Recent reports indicate that HMCs can often perform the work of multiple vertical centers, allowing for continuous operations without the need for frequent setups. This not only improves efficiency but also maximizes the utilization of machine time, essential for high-mix, high-repeat work environments.

A striking example of this efficiency is highlighted by a company that adopted four-axis horizontal machining, reportedly doubling their productivity by minimizing operation redundancies and drastically cutting cycle times. As manufacturing demands evolve, the adoption of horizontal machining technologies has become critical for companies aiming to maintain competitive advantage in the market. The shift toward HMCs continues to open new opportunities for diverse sectors, including aerospace and medical component production, where precision and speed are paramount. The industry's move toward horizontal centers signifies a broader trend in embracing innovations that drive efficiency and overall output in precision manufacturing.

Analyzing Market Trends: Growth Rates of Horizontal Machining Centers in Manufacturing

The market for horizontal machining centers is experiencing significant growth, aligning with the broader trends in precision manufacturing. An analysis of market data indicates that the metal cutting tools market is expected to grow dynamically, focusing on products like machining centers, lathes, and more. Specifically, projections indicate that the global metal cutting tool market will expand considerably, driven by needs in sectors like automotive and precision engineering.

In addition to the machining center market, the computer-aided manufacturing (CAM) sector is also on a trajectory of robust growth, with expectations to reach $6.567 billion by 2033, up from $3.394 billion in 2025. This represents a stable compound annual growth rate of 8.6%, underscoring the increasing demand for advanced manufacturing technologies. As industries strive for efficiency and precision, the integration of horizontal machining centers within manufacturing processes is set to play a pivotal role, facilitating higher production rates and improved accuracy.

This surge in demand is echoed across other related markets as well, such as the 3D metrology sector, predicted to grow from $12.6 billion in 2022 to $38.97 billion by 2029, achieving a compound annual growth rate of 17.5%. These statistics highlight the essential nature of modern manufacturing technologies in driving industry forward, as businesses embrace innovative solutions to remain competitive in a rapidly evolving market.

Unlocking Efficiency: Growth of Horizontal Machining Centers in Manufacturing

This bar chart illustrates the growth rate of horizontal machining centers in the precision manufacturing sector from 2019 to 2023. As seen, there has been a significant increase in growth, particularly in 2023, which highlights the rising efficiency and adoption of these technologies in the industry.

Key Benefits of Horizontal Machining Centers: Efficiency, Accuracy, and Cost Reduction

The rise of horizontal machining centers in precision manufacturing marks a significant advancement in efficiency and accuracy. These machines utilize multiple axes to perform complex cuts and operations in a single setup, drastically reducing the time spent on production. By streamlining processes, manufacturers can achieve faster turnaround times and minimize labor costs, while also enhancing the precision of their outputs. This shift not only leads to higher quality products but also contributes to a more efficient workflow.

Moreover, the incorporation of advanced technologies in horizontal machining centers allows for greater adaptability in manufacturing environments. Companies can quickly adjust their processes to meet varying demands, leading to significant cost reductions over time. As businesses continue to seek ways to optimize their operations, the benefits of these sophisticated machines become increasingly compelling. The projected growth in the CNC machine market further underscores the importance and effectiveness of horizontal machining centers in driving precision and productivity within the industry.

Unlocking Efficiency: The Rise of Horizontal Machining Centers in Precision Manufacturing

| Feature | Horizontal Machining Centers | Vertical Machining Centers |

|---|---|---|

| Efficiency | High production rates with reduced setup times | Moderate production rates |

| Accuracy | Tighter tolerances and better surface finishes | Good accuracy but less ideal for complex parts |

| Cost Reduction | Lower overall machining costs due to less waste | Higher costs due to longer machining times and setup |

| Flexibility | Ideal for complex geometries and multiple part orientations | Limited flexibility for multi-side machining |

| Machining Capability | Able to handle larger and heavier workpieces | Best for smaller, lighter parts |

Comparison of Horizontal and Vertical Machining Centers: Performance Metrics and Use Cases

In the realm of precision manufacturing, the choice between horizontal and vertical machining centers can significantly influence operational efficiency and product quality.

Horizontal machining centers are increasingly favored for their ability to handle complex part geometries and multi-surface processing, exemplified by advancements in models that emphasize high-torque performance. This makes them particularly well-suited for industries requiring intricate components, such as the medical field, where companies are optimizing their processes for high-flexibility, low-volume production.

Recent performance metrics indicate that businesses utilizing horizontal machining centers can achieve superior cycle times and enhanced material removal rates when compared to vertical counterparts. According to industry reports, horizontal machines can improve overall shop floor productivity by up to 30% due to their ability to accommodate larger workpieces and facilitate automated setups. Moreover, the integration of real-time monitoring technologies in horizontal machining processes is essential for maintaining optimal cutting conditions and reducing downtime, thereby maximizing production efficiency.

By harnessing these advancements, manufacturers are not only streamlining operations but also achieving higher accuracy and consistency in their outputs.

Future Prospects: The Role of Automation in Enhancing Horizontal Machining Efficiency

The rise of automation in the precision manufacturing sector, particularly in the deployment of horizontal machining centers, is a significant development in enhancing manufacturing efficiency. Automation is fundamentally transforming traditional manufacturing processes, enabling companies to achieve higher productivity levels and reduce operational costs. The integration of advanced technologies, including artificial intelligence and robotics, into horizontal machining has optimized precision in machining operations while minimizing human error.

As the demand for high-end CNC machine tools continues to grow, driven by the expansion of industries requiring precision components, the market for automation technologies is poised for substantial growth. The projected increase in the scale of CNC machinery applications, coupled with the rising trend of automation, suggests that manufacturers will increasingly rely on automated systems to meet their needs. This shift not only supports efficiency and accuracy but also opens new avenues for innovation within the manufacturing landscape, setting the stage for a future where fully automated machining processes become the norm in precision manufacturing.

Related Posts

-

How to Select the Right Vertical Machining Center for Your Manufacturing Needs

-

Exploring Top Alternatives to the Best Vertical CNC Machine for Global Buyers

-

7 Key Features That Make the Best Vertical Machining Centers Stand Out in 2023

-

Mastering Precision: A Step-by-Step Guide to Operating a 5 Axis Milling Machine

-

Exploring CNC Turning Center Applications: Innovative Examples Across Industries

-

Top Strategies for Enhancing Precision in CNC Boring Machine Operations