Exploring the Future of Horizontal Milling Machines at the 138th Canton Fair 2025: Industry Insights and Trends

As we look forward to the 138th Canton Fair in 2025, the spotlight on horizontal milling machines has never been more pronounced. The global market for milling machines is projected to reach USD 7 billion by 2026, reflecting a compound annual growth rate of about 5.1% from 2021 to 2026, according to a recent industry report by MarketsandMarkets. Horizontal milling machines, known for their versatility and efficiency, are playing a crucial role in this growth, particularly in sectors such as automotive, aerospace, and electronics. With advancements in technology and increasing demand for precision engineering, manufacturers are innovating to enhance productivity and reduce operational costs. Attending the Canton Fair will provide invaluable insights into the latest trends, key players, and emerging technologies within the horizontal milling machine sector, setting the stage for future developments and opportunities in the manufacturing landscape.

The Evolution of Horizontal Milling Machines in the Manufacturing Industry

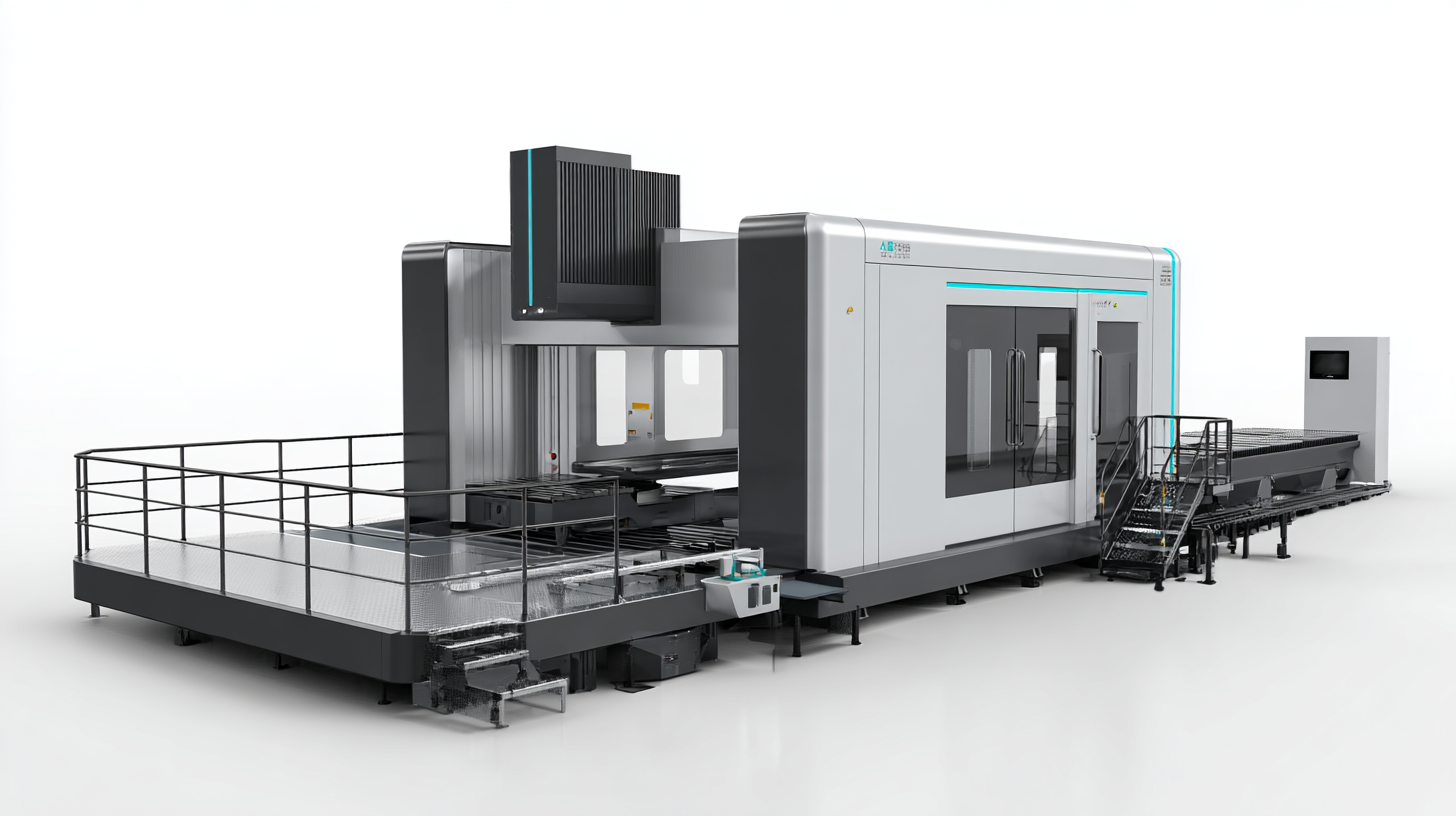

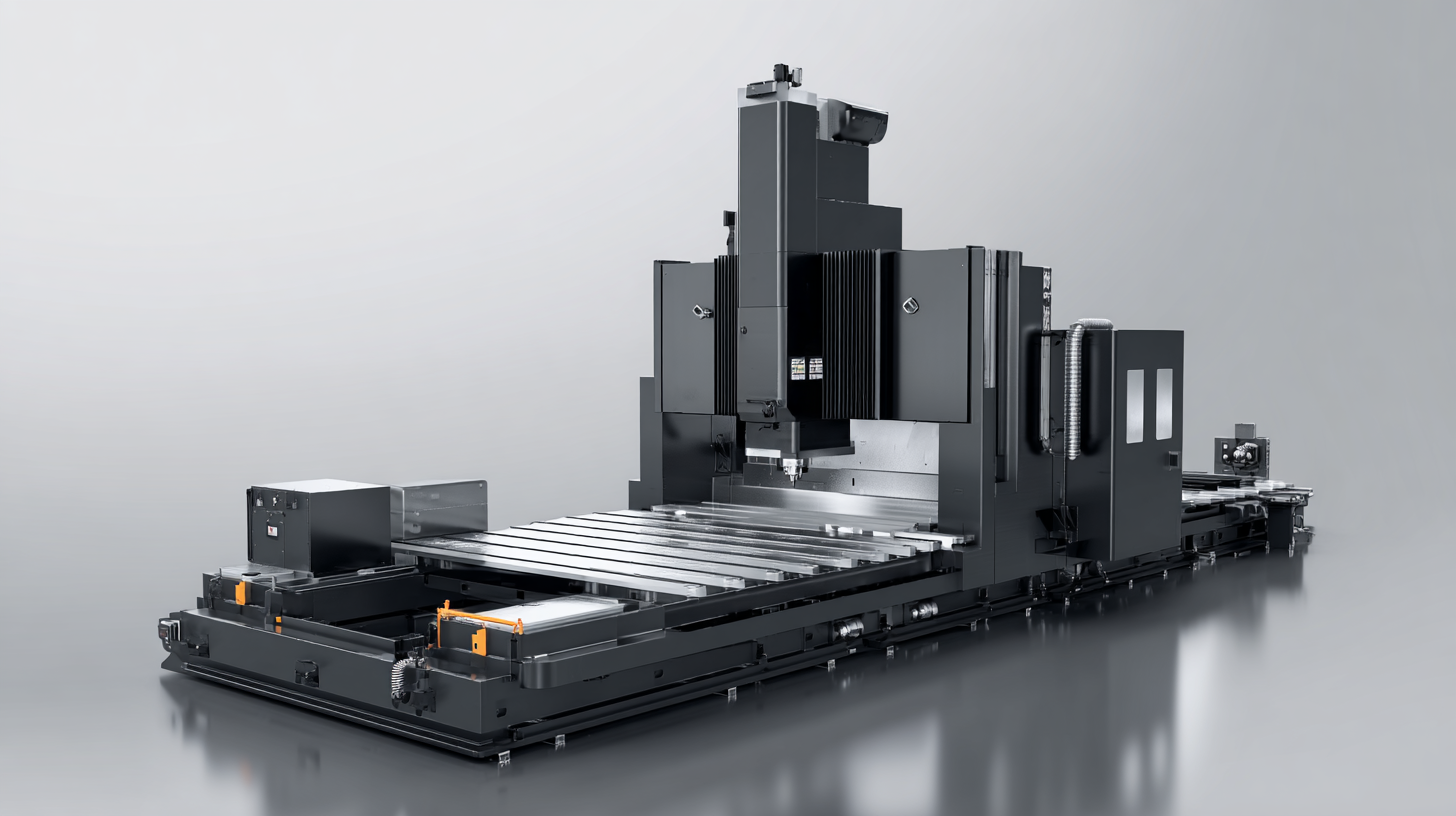

As manufacturing technology continues to evolve, horizontal milling machines have become increasingly sophisticated, offering higher accuracy and efficiency. The integration of new digital technologies into these machines has revolutionized how manufacturers approach metal machining. Not only do modern horizontal milling machines enhance productivity, but they also enable manufacturers to maintain tighter tolerances and improve product quality, responding effectively to the demands of various industries.

Tips for manufacturers considering upgrades include evaluating the potential return on investment for new milling technologies and exploring software solutions that optimize machine performance. Emphasizing training for operators on advanced machinery ensures that organizations can fully leverage these modern tools, leading to increased operational efficiency.

The metal machining market is on the rise, projected to grow significantly due to heightened infrastructure investments. Adopting AI-powered solutions within this sector is reshaping traditional practices, streamlining workflows, and driving innovation. Companies looking to stay competitive should consider implementing these technologies to not only boost production but also enhance their adaptability in a rapidly changing market landscape.

Exploring the Future of Horizontal Milling Machines at the 138th Canton Fair 2025: Industry Insights and Trends

| Feature | Current Industry Standard | Expected Future Trends |

|---|---|---|

| Automation | Manual machining with some automated features | Fully automated with AI integration |

| Precision | ±0.01 mm accuracy | ±0.005 mm accuracy with advanced sensors |

| Energy Efficiency | Standard motors | Smart energy management systems |

| User Interface | Basic control panel | Touchscreen interfaces with advanced diagnostics |

| Material Capabilities | Common metals and plastics | High-performance composites and exotic materials |

Key Trends in Horizontal Milling Technology for 2025

The horizontal milling machine market is poised for significant advancements by 2025, driven by emerging technologies and increasing demand across various industries. Key trends point towards enhanced automation and integration of smart technologies, including CNC capabilities, which facilitate precision and efficiency in milling processes. This shift is not only expected to streamline operations but also to minimize production costs, providing a competitive edge to manufacturers.

Additionally, sustainability will play a crucial role in shaping the future of horizontal milling technology. Manufacturers are increasingly focusing on developing energy-efficient machines that reduce waste and conserve resources. The integration of advanced materials and eco-friendly practices will likely become standard, reflecting a broader industry commitment to environmental stewardship and innovation. As these trends unfold, aligning with evolving market demands will be vital for industry stakeholders at the upcoming Canton Fair.

Innovations Showcased at the 138th Canton Fair for Milling Solutions

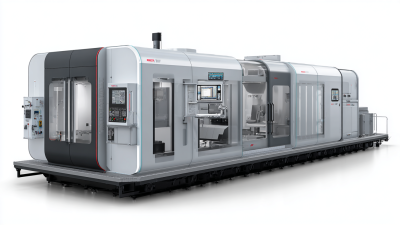

The 138th Canton Fair in 2025 is set to be a groundbreaking event for the milling industry, showcasing innovative solutions that promise to enhance productivity and precision in horizontal milling machines. Exhibitors will introduce advanced technologies, including smart automation and improved tooling systems, designed to meet the evolving demands of modern manufacturing. As companies increasingly prioritize efficiency and sustainability, this fair serves as an ideal platform for industry leaders to unveil their latest advancements.

When exploring new milling solutions at the Canton Fair, consider integrating automation into your workflow. Smart milling machines equipped with AI capabilities can optimize machining processes, reduce downtime, and increase throughput. Additionally, pay attention to exhibitors emphasizing energy-efficient technologies that not only lower operational costs but also contribute to a greener manufacturing environment.

While attending the fair, it’s beneficial to engage with industry experts and network with fellow professionals. Gather insights on the latest trends and best practices in milling technology. Networking can lead to potential collaborations and partnerships that could enhance your business operations and keep you ahead in this competitive landscape. Embracing innovation and adapting to emerging technologies will be critical for success in the future of milling.

Sustainability Practices in Horizontal Milling Machine Production

The 138th Canton Fair in 2025 promises to be a pivotal event for the horizontal milling machine industry, particularly with an increasing focus on sustainability practices in production. According to a recent report by MarketsandMarkets, the global machine tools market is expected to reach $161.3 billion by 2025, driven by the demand for more sustainable manufacturing processes. Many manufacturers are now prioritizing eco-friendly materials and energy-efficient machinery to reduce their carbon footprint, aligning with the industry's shift toward greener production methods.

Sustainability in horizontal milling machine production goes beyond just materials and energy efficiency; it also includes waste reduction and recycling initiatives. A study by Deloitte highlights that companies adopting sustainable practices can reduce their operating costs by up to 20%. With new innovations such as biodegradable lubricants and recyclable components, manufacturers at the Canton Fair will showcase how these changes can lead to improved product lifecycle management. As industry leaders gather to exchange insights, the fair will serve as a platform to highlight best practices and the future directions of sustainable manufacturing in the milling machine sector.

Exploring the Future of Horizontal Milling Machines: Sustainability Practices

This chart illustrates the adoption rates of various sustainability practices in horizontal milling machine production over the years.

Market Outlook: The Future Demand for Horizontal Milling Machines

The demand for horizontal milling machines is expected to see substantial growth in the coming years, driven by advancements in manufacturing technologies and increased automation. According to a report by MarketsandMarkets, the global horizontal milling machine market is projected to reach approximately $3.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.2% from 2020 to 2025. This growth is fueled by the rising need for precision machining in industries like aerospace, automotive, and medical device manufacturing, where horizontal milling machines deliver superior efficiency and accuracy.

Additionally, the integration of Industry 4.0 initiatives and smart manufacturing is influencing market dynamics. A survey conducted by Deloitte indicates that 70% of manufacturers are adopting advanced technologies, including CNC (Computer Numerical Control) in milling processes, to enhance productivity and reduce operational costs. As companies strive for more efficient production methods, the role of horizontal milling machines is becoming more pivotal, leading to increased investments in these machines, especially from developing economies where industrial expansion is rapid. The upcoming 138th Canton Fair in 2025 will likely showcase these emerging trends, providing a platform for industry stakeholders to explore the future innovations within this sector.

Related Posts

-

Discover Unmatched Manufacturing Excellence with the Best Horizontal Milling Machine from Leading Chinese Factories

-

Top Strategies for Enhancing Precision in CNC Boring Machine Operations

-

Future Trends in Horizontal Machining Centers for Global Buyers in 2025

-

10 Reasons Why the Best CNC Turning Machine is Essential for Your Business

-

Unveiling the Technical Specifications of the Best Vertical CNC Machines for Global Buyers

-

Solutions for Achieving Precision with the Best CNC Horizontal Boring Mill