Future Trends in Horizontal Machining Centers for Global Buyers in 2025

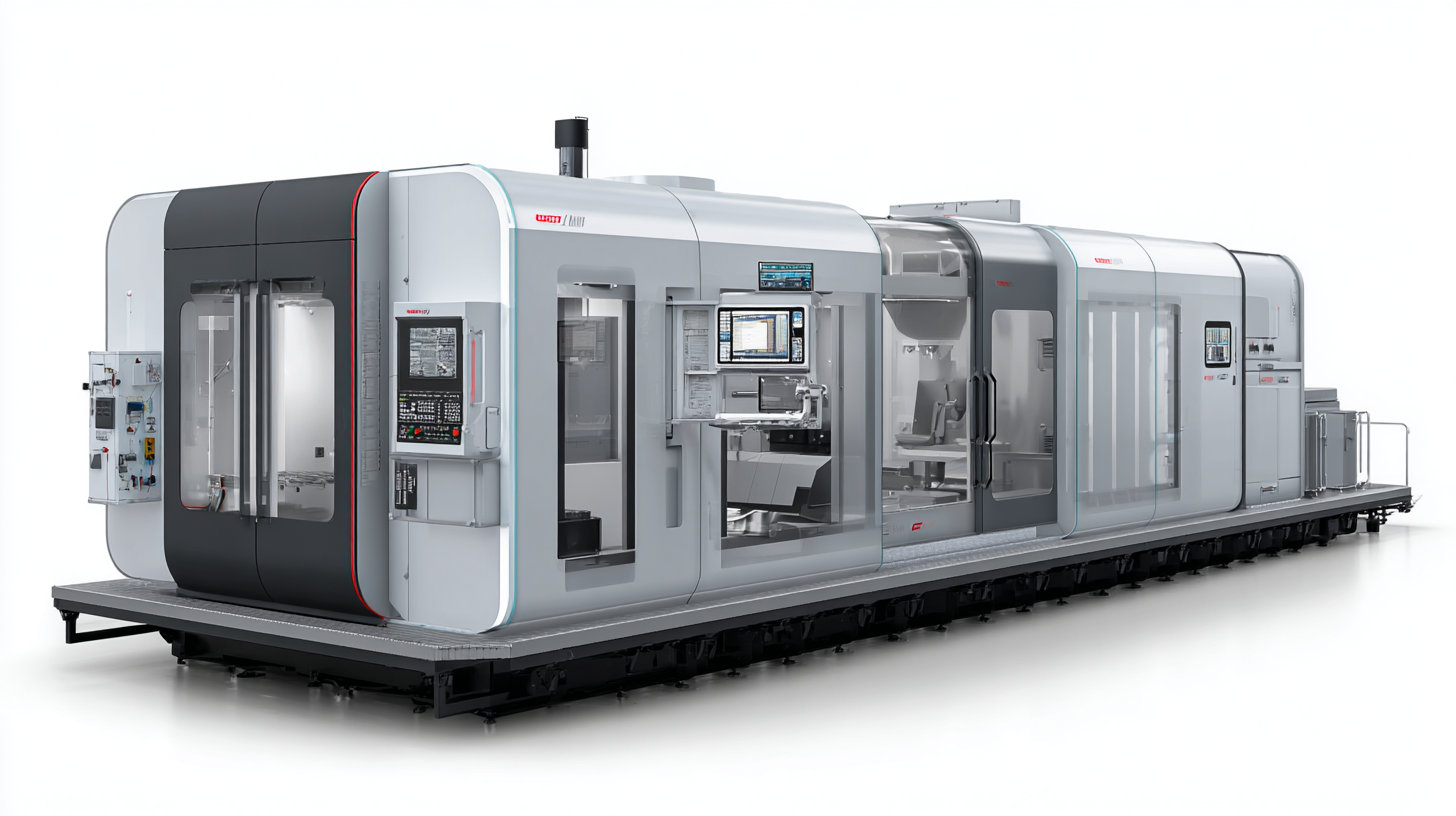

As we approach 2025, the landscape of manufacturing is being significantly influenced by advancements in technology, prompting global buyers to reassess their investments in horizontal machining centers. According to a recent report by MarketsandMarkets, the global market for machining centers is projected to reach USD 8.53 billion by 2026, growing at a CAGR of 4.2%. This growth is primarily driven by the increasing demand for more precise and efficient machining solutions across various industries, including aerospace, automotive, and medical. Horizontal machining centers are becoming increasingly vital due to their ability to enhance productivity and manufacturing precision. As manufacturers look towards the future, they must adapt to emerging trends such as automation, Industry 4.0 integration, and sustainability practices, which are poised to redefine operational efficiencies in the machining sector. Understanding these trends will be crucial for global buyers seeking to remain competitive in an evolving market.

Future Market Projections for Horizontal Machining Centers by 2025

As we look towards 2025, the market for horizontal machining centers is set to transform significantly, driven by advancements in technology and rising global demand. With the automation of machining processes becoming increasingly sophisticated, we anticipate notable enhancements in efficiency and precision. Companies are expected to invest heavily in Research and Development (R&D) to integrate artificial intelligence and smart technology into their machining centers, optimizing production lines and helping manufacturers stay competitive in a rapidly evolving landscape.

Moreover, projections indicate a substantial increase in the global market value of horizontal machining centers. The anticipated growth in associated industries—such as automotive and aerospace manufacturing—will further contribute to this demand. Buyers should be prepared to embrace innovations that not only enhance operational capabilities but also align with sustainable practices, catering to an eco-conscious market. As a result, investing in the latest machining technologies will be crucial for businesses planning to thrive in the competitive environment of 2025.

Future Trends in Horizontal Machining Centers for Global Buyers in 2025

Projected trends in the horizontal machining center market indicate a significant growth trajectory, with expected market sizes reaching $5000 million by 2025. This chart illustrates the anticipated increase from 2023 to 2025, highlighting the demand for advanced machining technologies.

Key Innovations Driving Industry Growth in Horizontal Machining Technology

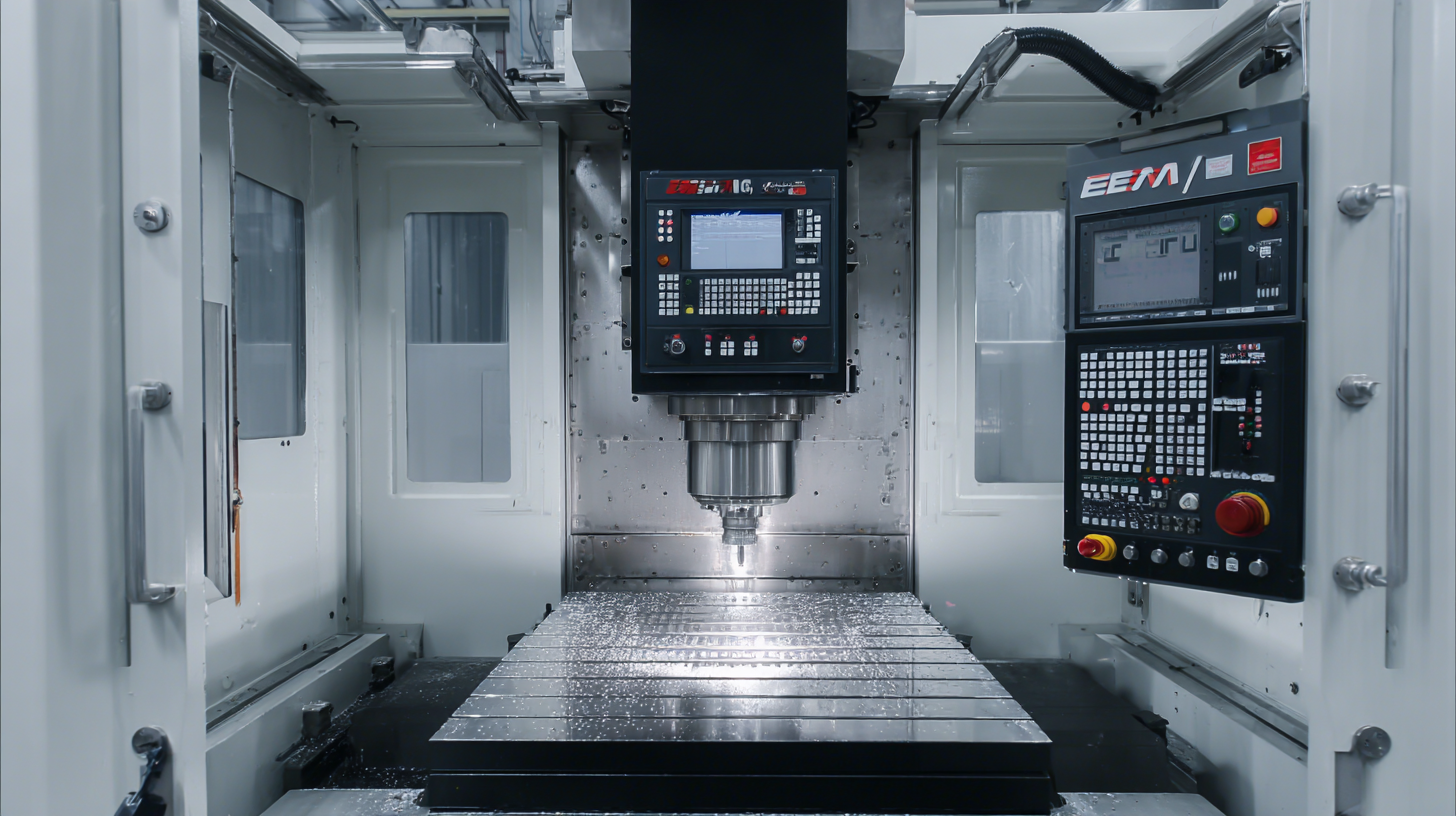

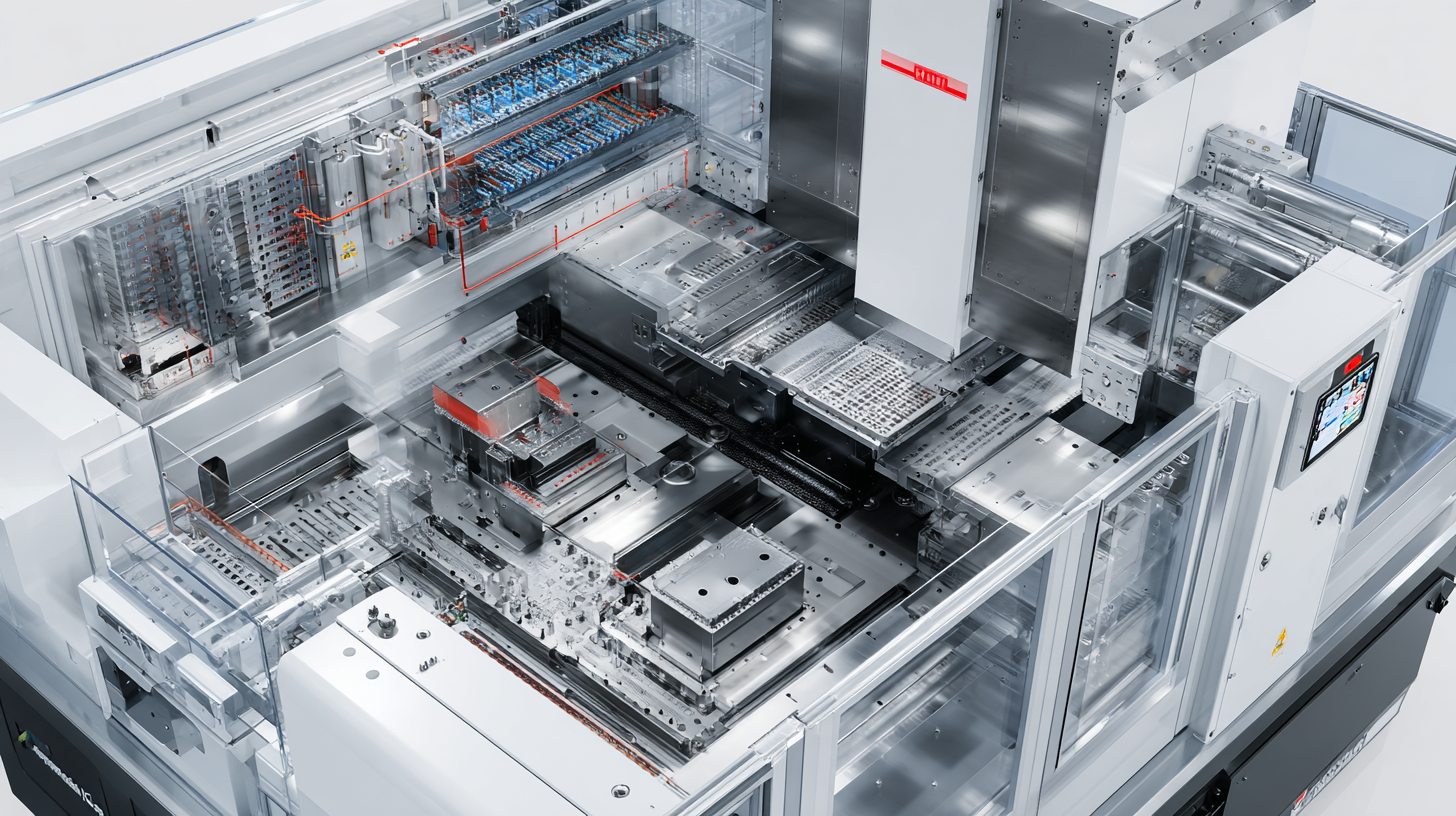

The horizontal machining center (HMC) industry is poised for significant transformation by 2025, driven by key innovations that address the increasing demands for efficiency and sustainability. As manufacturers continue to pivot towards smart manufacturing technologies, the integration of artificial intelligence and the Internet of Things (IoT) into HMCs stands at the forefront. These advancements not only enhance precision and productivity but also play a crucial role in reducing energy consumption and carbon emissions—critical factors highlighted in recent government reports on sustainable industrial practices.

According to industry forecasts, the global market for high-precision gear reducers, essential components in HMCs, is projected to experience rapid growth, reflecting a compound annual growth rate of over 11% from 2023 to 2031. The shift towards regenerative resources in key sectors, such as the non-ferrous metals industry, underscores a broader commitment to recycling and sustainability in manufacturing processes. By adopting advanced technologies, companies can achieve lower operational costs and environmental impacts, aligning with global trends towards circular economies.

Tips: When considering investments in horizontal machining technology, buyers should prioritize equipment that offers advanced automation capabilities and is compatible with recycling practices. Additionally, assessing suppliers based on their commitment to sustainability can provide long-term advantages. As the industry evolves, embracing innovations that drive efficiency and environmental responsibility will be essential for maintaining a competitive edge.

The Role of Digital Transformation in Horizontal Machining Centers

In 2025, the landscape of horizontal machining centers (HMCs) will be significantly reshaped by digital transformation. As manufacturers strive for efficiency and precision, the integration of advanced technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) will play a pivotal role. These innovations will enable real-time monitoring and predictive maintenance, reducing downtime and increasing the reliability of machining operations. Buyers will look for HMCs equipped with smart sensors and analytics capabilities that provide actionable insights, thus optimizing workflows and enhancing productivity.

The shift towards digitalization will not only improve operational efficiency but also facilitate a more agile manufacturing environment. With the rise of Industry 4.0, HMCs will increasingly incorporate cloud-based solutions that allow for seamless data sharing and remote management. This connectivity empowers global buyers to adapt swiftly to changing market demands and customer preferences. Moreover, the emphasis on sustainability will drive the development of energy-efficient machines that minimize waste and carbon footprint. As digital transformation becomes integral to horizontal machining, future buyers will seek cutting-edge solutions that not only meet their production needs but also align with their sustainability goals.

Export and Import Certification Trends Impacting Global Machining Buyers

As global buyers prepare for the trends in horizontal machining centers by 2025, understanding the evolving landscape of export and import certification is crucial. With different countries tightening their regulations, the ability to navigate these complexities can significantly impact procurement strategies. Buyers must stay informed about the certification requirements imposed by both exporting and importing countries, as non-compliance can lead to delays and added costs.

**Tip:** Regularly consult with trade compliance experts to ensure that your processes align with the latest regulations. This proactive approach will help mitigate risks associated with unexpected certification requirements and keep your supply chain efficient.

Moreover, the trend toward increasing environmental standards in machining processes is palpable. Global buyers should not only focus on obtaining necessary certifications but also consider suppliers that prioritize sustainability. This commitment can enhance your brand's reputation and appeal to environmentally conscious consumers.

**Tip:** When selecting suppliers, inquire about their certifications related to sustainability and environmental impact. This information can provide a competitive edge and potentially open doors to new markets that favor eco-friendly practices.

Understanding Consumer Preferences in the Horizontal Machining Market

As we approach 2025, understanding consumer preferences in the horizontal machining market becomes essential for global buyers. A keen focus on customer needs has transformed the landscape of manufacturing, particularly in machining centers. Buyers are increasingly looking for machines that are not only efficient but also versatile enough to handle a multitude of materials and complex designs. The demand for high precision, increased automation, and integration with digital technologies such as IoT and AI is driving innovation in this sector, compelling manufacturers to align their offerings with these trends.

Moreover, sustainability is becoming a critical factor influencing consumer choices. Buyers are more inclined to invest in machining centers that prioritize energy efficiency and reduce waste. This shift reflects a broader commitment to environmental responsibility, with many companies actively seeking equipment that supports their sustainability goals. Additionally, user-friendly interfaces and robust support services are being prioritized, as customers value ease of operation and reliable maintenance. Manufacturers that recognize and adapt to these evolving preferences will likely gain a competitive edge in the dynamic horizontal machining market.