Ultimate Guide to Mastering Lathe CNC Machine Techniques for Precision Engineering

In the world of precision engineering, mastering the techniques associated with the lathe CNC machine is crucial for achieving exceptional results. As technology continues to evolve, the complexity of operations and the problems that arise during machining processes become more pronounced. This blog aims to address common issues faced by both novice and experienced operators when working with lathe CNC machines. From programming challenges to material inconsistencies, understanding these problems is essential for optimizing performance and ensuring high-quality output. By delving into the intricacies of lathe CNC machine techniques, we will uncover practical solutions and best practices to enhance your machining skills and minimize errors, ultimately leading to greater efficiency and precision in your engineering projects.

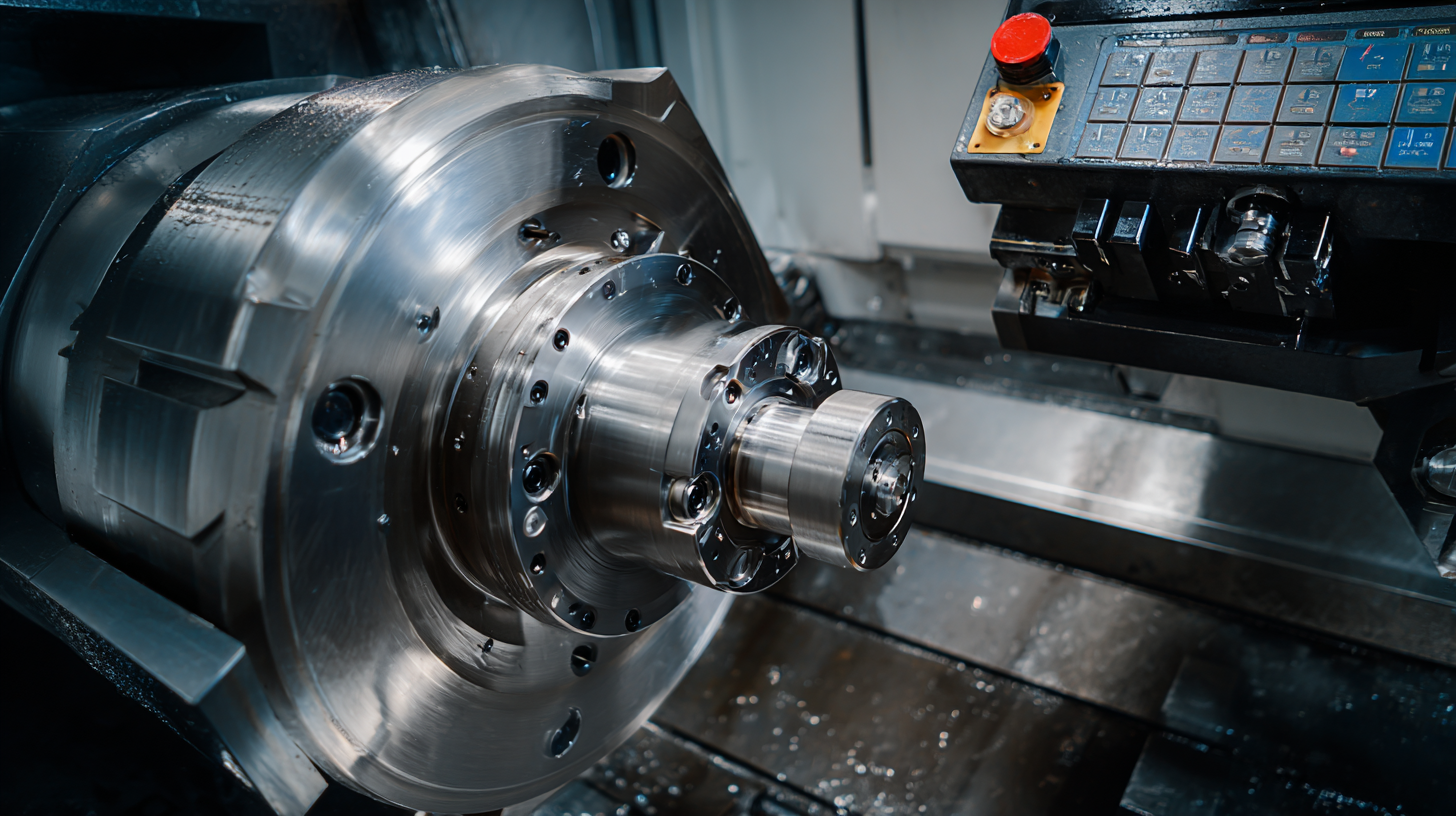

Techniques for Achieving Precision with CNC Lathe Machines

Achieving precision with CNC lathe machines requires a combination of advanced techniques, technical knowledge, and hands-on experience. One of the fundamental techniques is mastering the toolpath strategy. A well-planned toolpath minimizes unnecessary movements and optimizes the cutting time while enhancing precision. Using software simulations can preview the toolpath to identify potential errors before the actual machining process begins. Ensuring that the tool is correctly set up and calibrated is also crucial, as even minor deviations can lead to inaccuracies in the final product.

Another critical technique is understanding and selecting the right cutting tools and parameters. Different materials require specific tools and cutting speeds to produce precise results. For instance, using carbide tools can enhance performance when machining hard materials, while high-speed steel tools are ideal for softer materials. Furthermore, adjusting the feed rate and depth of cut according to the material type and desired finish can significantly impact the precision of the final output. Employing consistent tool maintenance and regular checks can prevent wear and tear, ensuring that the tools perform optimally throughout the machining process.

Ultimate Guide to Mastering Lathe CNC Machine Techniques for Precision Engineering - Techniques for Achieving Precision with CNC Lathe Machines

| Technique | Description | Material Type | Precision Level (μm) | Applications |

|---|---|---|---|---|

| Turning | Removing material by rotating the workpiece against a cutting tool. | Metals | 10 | Shafts, Bushings |

| Facing | Smoothening the surface at the end of the workpiece. | Plastics | 5 | Housings, Seals |

| Threading | Cutting helical grooves for screws or bolts. | Steel | 20 | Fasteners, Connectors |

| Grooving | Creating a slot or groove on the workpiece. | Aluminum | 15 | Mounting Brackets, Fixtures |

| Boring | Enlarging a hole that has already been drilled. | Copper | 8 | Housings, Valves |

Common Challenges in CNC Lathe Operations and Effective Solutions

CNC lathe operations are integral to precision engineering, yet they come with a set of common challenges that can hinder efficiency and productivity. One notable challenge involves the transition from traditional manual processes to advanced digital solutions. A report indicated that 70% of manufacturers identify skills gaps due to a retiring workforce, which emphasizes the need for training and adaptation in CNC operations. Implementing digital twins, which offer virtual representations of physical systems, can enhance understanding and control in lathe operations, thus facilitating smoother transitions and informed decision-making.

Additionally, the rise of generative AI technologies is proving vital in addressing manufacturing challenges. These tools can optimize design processes and automate routine tasks, enabling engineers to focus on complex problem-solving. Data indicates that embracing such technologies can accelerate digitalization efforts by up to 30%, showcasing their transformative potential. As companies strive to overcome hurdles related to equipment maintenance and data management, investing in modern solutions is becoming essential for staying competitive in a rapidly evolving landscape.

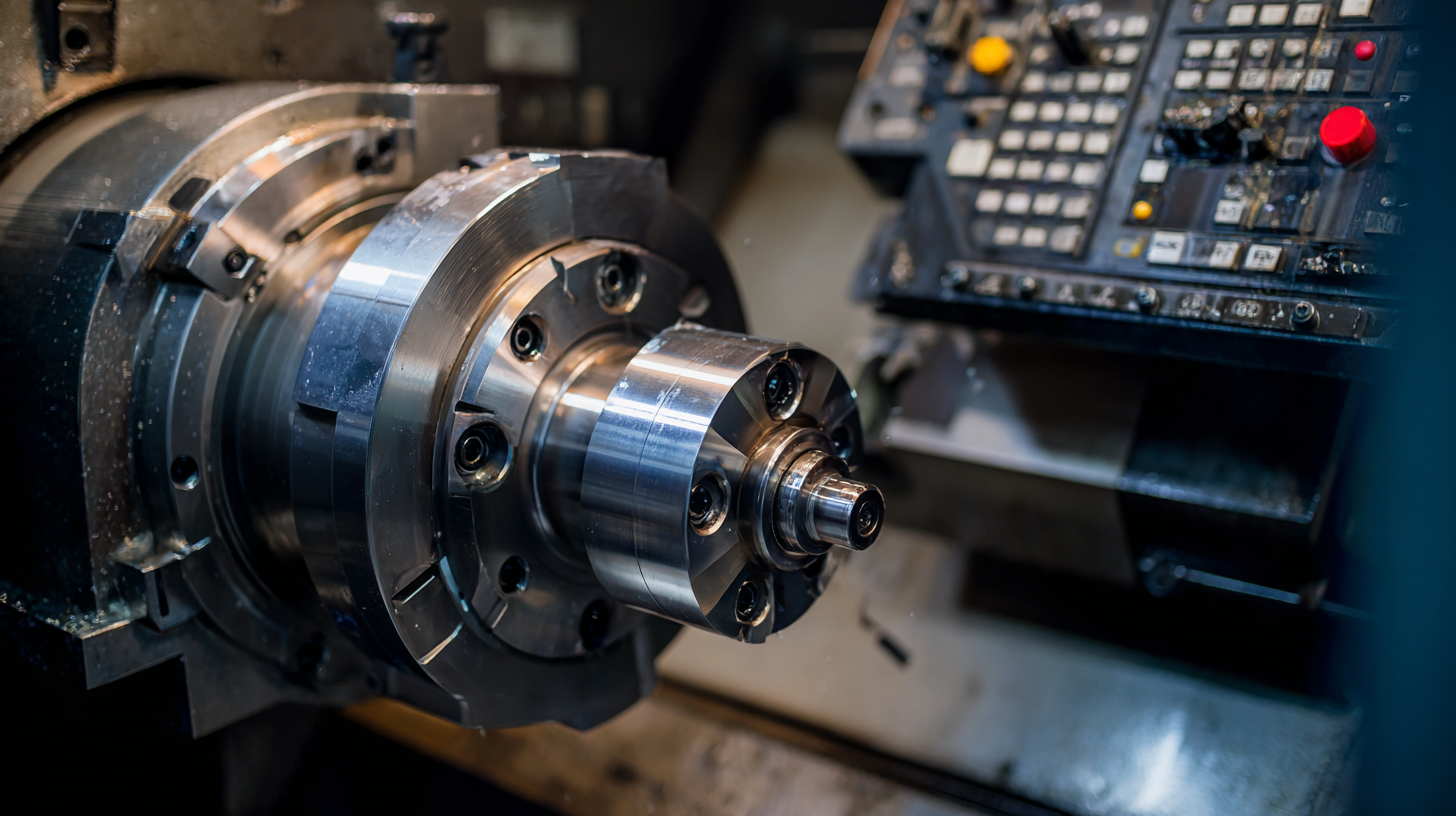

Essential Tools and Software for Optimizing Lathe CNC Performance

When it comes to optimizing the performance of your lathe CNC machines, selecting the right tools and software is essential. High-quality cutting tools are fundamental for achieving precision and efficiency. Invest in carbide inserts or specialized tool bits designed for your specific materials, as they enhance durability and reduce wear, ultimately leading to better surface finishes.

Additionally, using the right software can streamline operations and significantly improve workflow. CAD/CAM software enables users to create intricate designs and generate precise tool paths efficiently. Incorporating simulation software allows for the testing of tool paths before actual machining, helping to identify potential issues and reduce material waste.

Tip: Regularly update your software to access the latest features and optimizations, ensuring you stay at the forefront of technology in precision engineering. Also, don’t forget to maintain your tools meticulously; proper cleaning and storage can extend their lifespan and enhance their performance over time.

Best Practices for Maintenance and Troubleshooting in CNC Lathes

When it comes to maintaining CNC lathes, adopting best practices for maintenance and troubleshooting is crucial for ensuring optimal performance and longevity. One of the most effective strategies is implementing a predictive maintenance program powered by artificial intelligence. This approach allows operators to receive reliable maintenance recommendations, minimizing unexpected failures and enhancing overall machine efficiency. By accurately predicting when maintenance is needed, manufacturers can dramatically reduce downtime—up to 90 percent—transforming potential breakdowns into planned maintenance activities.

Additionally, addressing common challenges in CNC operations can significantly improve both productivity and precision. Utilizing techniques such as direct coolant application to the cutting edge not only aids in heat management but also enhances chip evacuation and surface finish. Machine tool digitalization plays an essential role in monitoring tool wear and breakage, ensuring that manufacturers can squeeze the maximum value out of their machinery. As the demand for efficiency grows in the manufacturing sector, these best practices for maintenance and troubleshooting will become pivotal in achieving high standards in precision engineering.

Lathe CNC Machine Performance Analysis

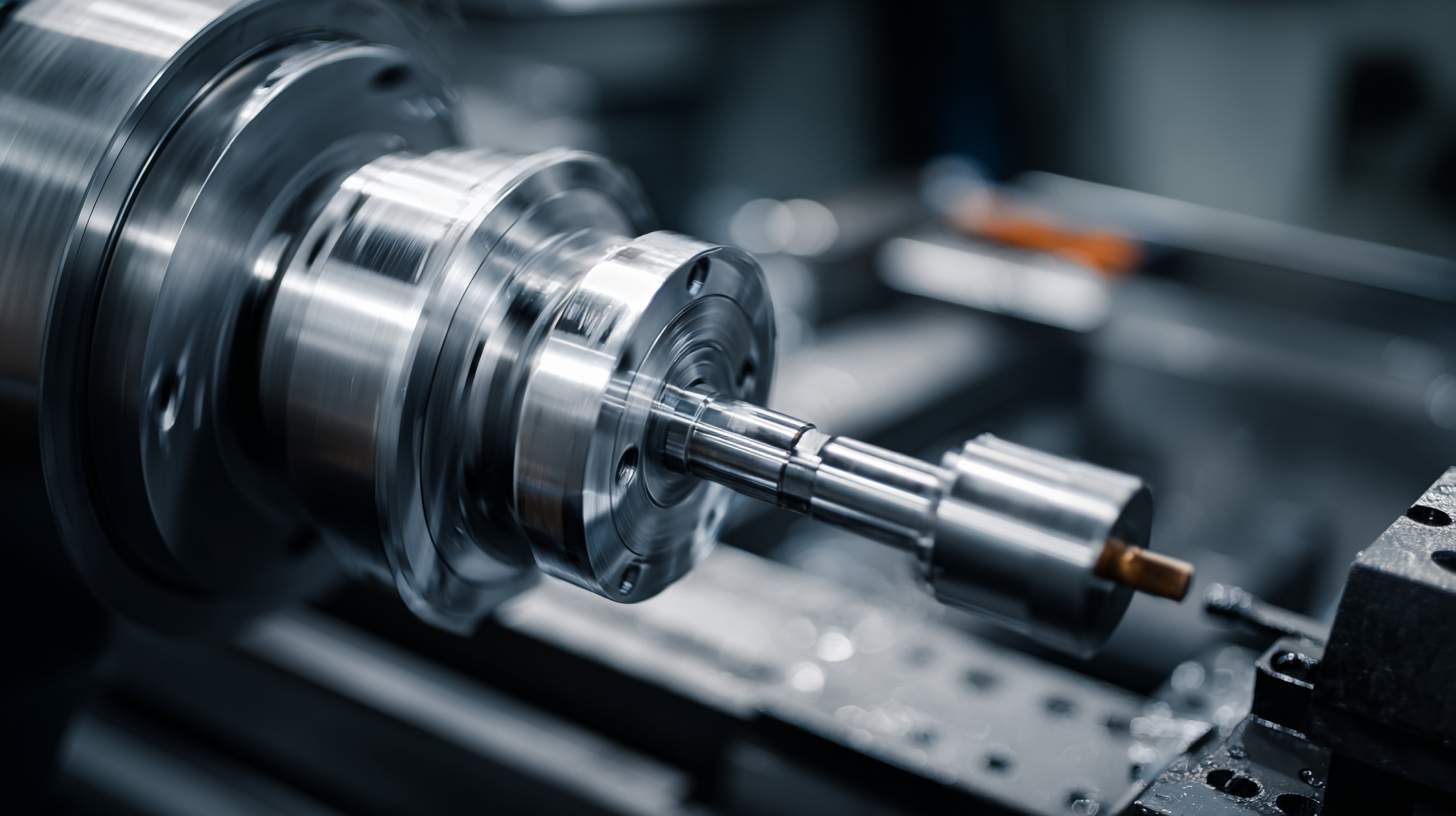

Advanced Machining Strategies for Enhanced Efficiency and Accuracy

In the realm of precision engineering, mastering lathe CNC machine techniques is vital for achieving enhanced efficiency and accuracy. Advanced machining strategies play a crucial role in optimizing production processes and ensuring output quality. By integrating innovative technologies and methodologies, such as machine learning, manufacturers can analyze data collected from CNC operations to identify patterns and areas for improvement. This not only streamlines workflows but also significantly reduces errors, ensuring that the machined parts meet stringent specifications.

Recent advancements in digital manufacturing further highlight the importance of adopting cutting-edge technologies. Precision machining shops that have transitioned to digital systems have reported substantial gains in operational effectiveness. Utilizing data-driven techniques, such as advanced gap imputation algorithms, enables these facilities to maintain high levels of data quality, which is essential for decision-making and process optimization. By leveraging machine learning and intelligent automation, businesses in the CNC machine market can enhance their capabilities, driving growth and competitiveness in an evolving landscape.