Top Strategies for Maximizing Efficiency with Large Milling Machines

In the rapidly evolving landscape of manufacturing, the optimization of processes using large milling machines has become a pivotal focal point for businesses aiming to enhance productivity and reduce operational costs. According to a report by Grand View Research, the global CNC milling machine market is expected to reach $100 billion by 2025, demonstrating a compounded annual growth rate of 5.3%. This growth underscores the significance of maximizing the efficiency of large milling machines that perform critical functions in diverse applications, from aerospace to automotive industries. By employing strategic methodologies, manufacturers can leverage advanced technologies and best practices to streamline operations, reduce waste, and improve turnaround times. This blog will delve into top strategies that can be implemented to achieve greater efficiency and profitability in the utilization of large milling machines.

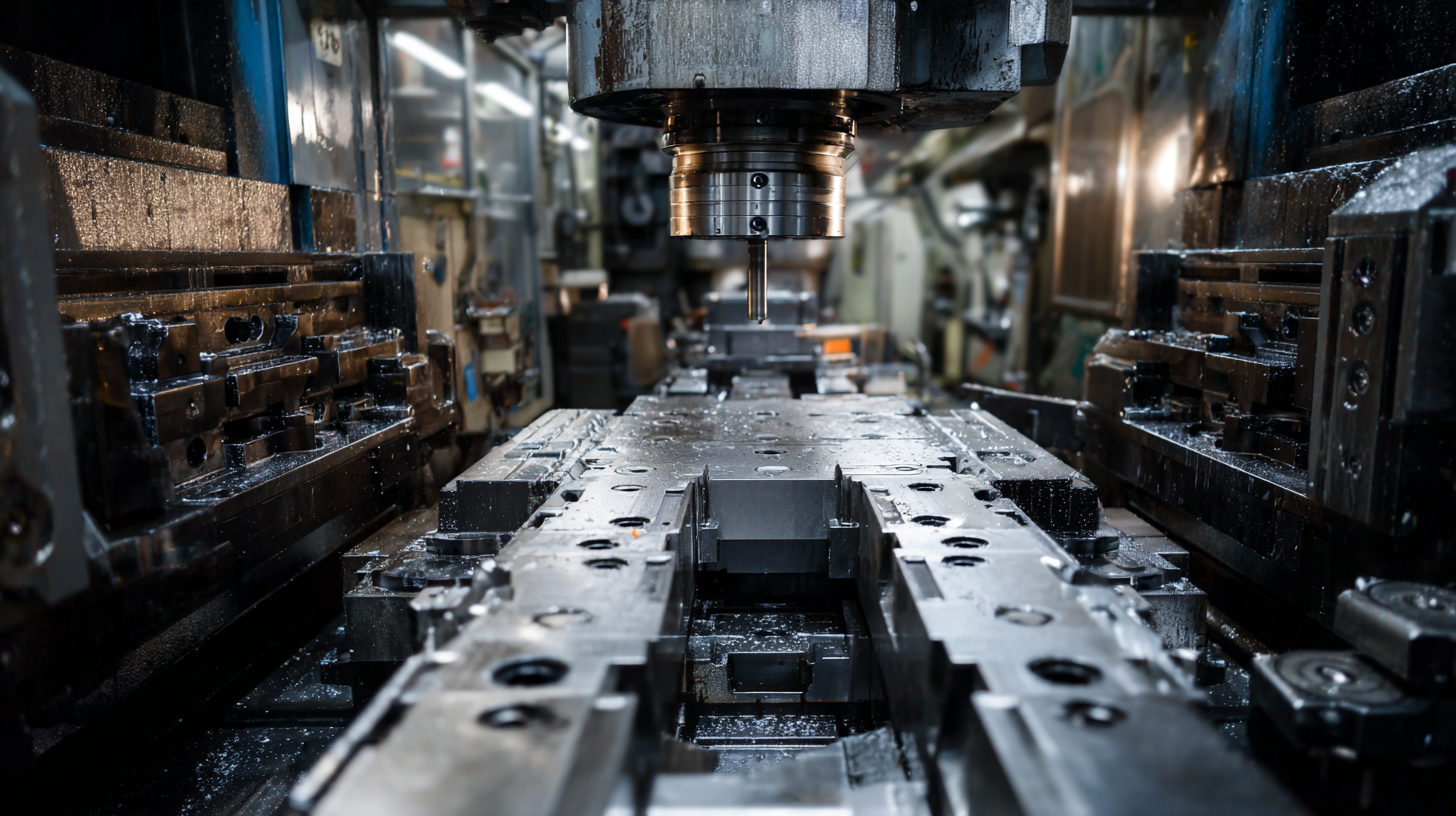

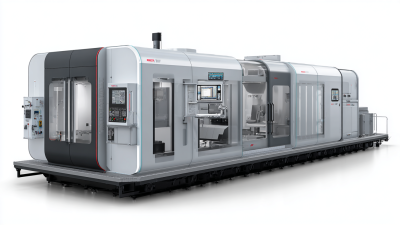

Innovative Technologies Revolutionizing Large Milling Machines

Innovative technologies have transformed the landscape of large milling machines, enhancing both their efficiency and capabilities. One significant advancement is the integration of automation and artificial intelligence (AI) in milling operations. By utilizing smart algorithms, machines can now better analyze data in real-time, optimizing cutting paths and minimizing downtime. This not only leads to significant time savings but also enhances precision, allowing for more intricate designs and tighter tolerances in processed materials.

Another technology shaping the future of large milling machines is the adoption of advanced materials and coatings. High-performance tooling made from innovative composites and coated with durable materials can withstand higher temperatures and reduce wear and tear. This results in increased tool life and consistent performance, enabling manufacturers to maintain productivity without the need for frequent replacements. Furthermore, modern milling machines are now equipped with improved sensors and feedback systems, enabling continuous monitoring and predictive maintenance, thus preventing unplanned breakdowns and extending the lifespan of the equipment.

Best Practices for Maintenance to Enhance Milling Efficiency

Proper maintenance is critical to enhancing the efficiency of large milling machines. According to a report from the National Tooling and Machining Association, regular preventive maintenance can increase production efficiency by up to 20%. To achieve this, operators should implement a strict schedule for inspecting and servicing key components such as bearings, belts, and lubrication systems. Ensuring that these parts are in optimal condition reduces downtime and enhances the overall performance of milling operations.

**Tip:** Regularly check and calibrate the machine settings to maintain accuracy in milling. A slight miscalibration can lead to increased wear and tear, ultimately affecting output quality and efficiency.

Moreover, keeping machines clean and free of debris is essential. A study by the Precision Metalforming Association indicates that unclean work areas fail to streamline operations and can even lead to costly repairs. Simple practices like regular cleaning of coolant tanks and checkpoints will not only prolong machine life but also ensure that milling processes are consistently efficient.

**Tip:** Implement a daily checklist for maintenance tasks. This habit facilitates quick identification of potential issues before they escalate into significant repairs. Consistent diligence in machine upkeep translates directly into productivity gains.

Top Strategies for Maximizing Efficiency with Large Milling Machines

This chart illustrates the performance metrics of large milling machines under various maintenance strategies. It highlights the relationship between maintenance frequency and overall milling efficiency.

Optimizing Tool Selection for Cost-Effective Milling Operations

When it comes to milling operations, the selection of tools plays a critical role in both efficiency and cost management. Choosing the right tooling materials and geometries can lead to significant cost savings while enhancing the performance of large milling machines. High-speed steel (HSS) and carbide tools are the most common options; however, the nature of the material being machined should dictate the choice. For softer materials, HSS may be sufficient, but for harder metals, carbide tools often yield better results due to their heat resistance and durability.

Furthermore, understanding the specific cutting parameters—such as feed rate, speed, and depth of cut—can help maximize tool life and optimize performance. Utilizing advanced tool path software can aid operators in making informed decisions about tool selection based on the unique requirements of each project.

It’s also beneficial to regularly assess the performance of existing tools and adjust strategies accordingly, incorporating newer technologies or tools as they become available. By focusing on these aspects of tool selection, businesses can enhance efficiency and reduce operational costs in their milling operations significantly.

Data-Driven Approach: Leveraging Analytics for Process Improvement

In the realm of industrial manufacturing, the need for efficiency has become more pressing than ever, particularly when it comes to large milling machines. Adopting a data-driven approach can significantly enhance process improvement by harnessing the power of analytics. By collecting and analyzing operational data, manufacturers can identify inefficiencies that may traditionally go unnoticed. This could include anything from machine downtime to excessive tool wear, which can be quantified and addressed systematically.

Leveraging predictive analytics is another crucial strategy for maximizing efficiency. By anticipating potential issues before they arise, operators can schedule maintenance proactively, reducing unplanned outages and keeping production lines running smoothly. Furthermore, data visualization tools can provide insights into complex datasets, allowing decision-makers to quickly spot trends and make informed choices about resource allocation and process adjustments. As a result, the integration of data analytics into the milling process not only boosts productivity but also enhances the overall quality of the output, ensuring that operations remain competitive in an ever-evolving market.

Top Strategies for Maximizing Efficiency with Large Milling Machines

| Strategy | Description | Improvement (%) | Implementation Time (weeks) | ROI (Return on Investment) |

|---|---|---|---|---|

| Predictive Maintenance | Utilize analytics to predict equipment failures before they occur. | 25% | 8 | 200% |

| Real-time Monitoring | Implement IoT solutions to monitor machine performance in real-time. | 30% | 5 | 150% |

| Scheduling Optimization | Use analytics for effective scheduling of machine operations to reduce downtime. | 20% | 4 | 175% |

| Process Standardization | Standardize machining processes based on data-driven insights. | 22% | 6 | 160% |

| Training and Development | Invest in continuous training to enhance staff capabilities. | 15% | 12 | 130% |

Training Workforce for Advanced Milling Techniques and Safety

In the world of large milling operations, a well-trained workforce is the backbone of efficiency and safety. Investing in comprehensive training programs enables employees to master advanced milling techniques, which not only enhances productivity but also reduces the risk of accidents. By focusing on skill development, companies can ensure that their workers are adept at operating complex machinery, interpreting technical specifications, and troubleshooting issues that may arise during the milling process.

Furthermore, safety should never be an afterthought in any milling setup. Training programs must incorporate rigorous safety protocols and best practices. Workers need to be educated on the potential hazards associated with operating large milling machines and the necessary precautions to mitigate these risks. By fostering a culture of safety through ongoing education and hands-on training, organizations can minimize the likelihood of workplace accidents, ensuring that employees return home safely at the end of each shift while also improving overall operational efficiency.

Related Posts

-

Overcoming Global Standards Challenges: The Search for the Best Milling Machine

-

Exploring Top Alternatives to the Best Vertical CNC Machine for Global Buyers

-

Unveiling the Technical Specifications of the Best Vertical CNC Machines for Global Buyers

-

Ultimate Guide to Mastering Lathe CNC Machine Techniques for Precision Engineering

-

7 Reasons Why the Best 5 Axis CNC Milling Machines Are Essential for Modern Manufacturing

-

Future Trends in Horizontal Machining Centers for Global Buyers in 2025