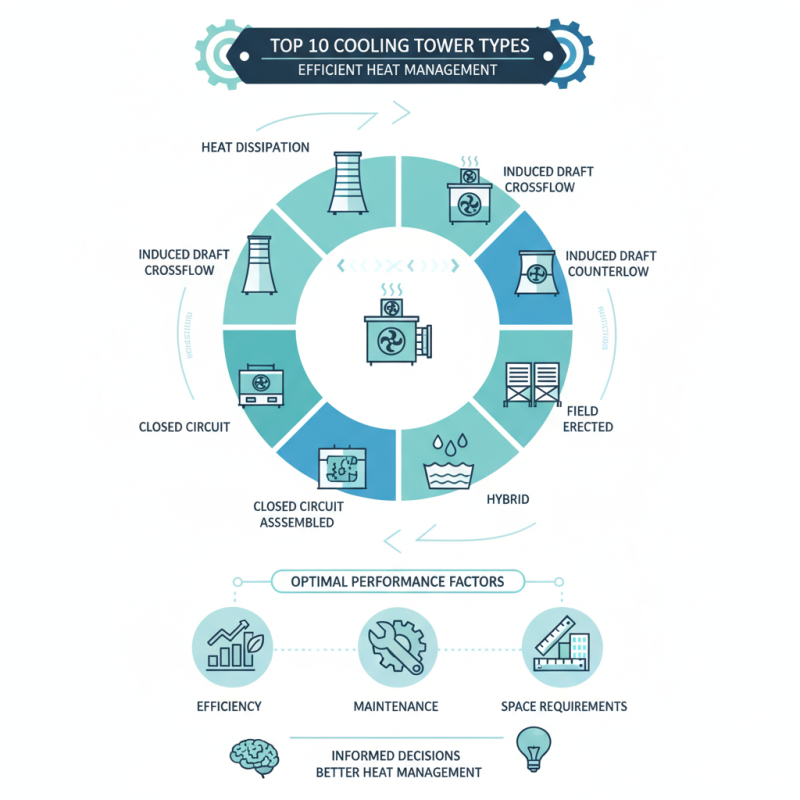

Top 10 Cooling Tower Types for Efficient Heat Management?

cooling towers play a crucial role in industrial and commercial applications. They manage heat by dissipating excess thermal energy. Different types of cooling towers offer various benefits.

Each cooling tower has its unique design and functionality. Some are more efficient in specific environments, while others may struggle under certain conditions. Choosing the right cooling tower is essential for optimal performance. It directly affects energy consumption and operational costs.

Understanding the top types of cooling towers can help businesses make informed decisions. It is vital to consider factors like efficiency, maintenance, and space requirements. Reflecting on these elements will lead to better heat management solutions.

Overview of Cooling Tower Types in Heat Management Applications

Cooling towers play a vital role in heat management applications across various industries. They help dissipate heat from systems by transferring it to the atmosphere. According to the International Energy Agency (IEA), industrial cooling accounts for about 20% of global energy consumption. Therefore, selecting the right type of cooling tower is crucial for efficiency.

Wet cooling towers are considered the most effective. They utilize water evaporation to enhance cooling, often achieving efficiency rates over 90%. However, they may be less ideal in areas with water shortages or strict regulations. Dry cooling towers, in contrast, do not use water. They work well in arid regions but can struggle in high ambient temperatures. Research indicates that dry cooling systems can raise capital costs by up to 30% compared to wet systems.

Hybrid cooling towers offer a compromise. They combine features of both wet and dry systems, adjusting operation based on environmental conditions. This flexibility can improve overall efficiency. Yet, they may require more complex maintenance routines. As industries strive for sustainability, the rise of advanced cooling solutions becomes imperative. The right choice leads to lower energy use and reduced operational costs, but understanding each type remains a challenge.

Comparison of Natural Draft and Mechanical Draft Cooling Towers

Natural draft and mechanical draft cooling towers play vital roles in heat management. Each type has unique features that affect their efficiency. Natural draft towers utilize buoyancy for air circulation. They are typically taller, designed to enhance airflow. Mechanical draft towers, on the other hand, rely on fans for air movement. This allows for more controlled cooling processes.

Tips for choosing the right type include understanding your facility's needs. Natural draft towers are ideal for large-scale operations. They usually require less energy to operate. However, they need significant space and may not fit every site. Mechanical draft towers offer flexibility in design. They can be installed in various configurations, making them suitable for limited spaces.

Keep in mind that maintenance is crucial for both types. Neglect can lead to inefficiencies and unexpected downtime. Regular inspections ensure proper operation and prevent costly repairs. It's essential to evaluate your cooling requirements and budget. Choosing the right cooling tower type can enhance overall productivity and efficiency. Don't rush this decision; consider all factors carefully.

Top 10 Cooling Tower Types for Efficient Heat Management

| Cooling Tower Type | Draft Type | Efficiency (%) | Water Consumption (L/s) | Cost ($/unit) |

|---|---|---|---|---|

| Counterflow Cooling Tower | Mechanical Draft | 90 | 1.5 | 1500 |

| Crossflow Cooling Tower | Mechanical Draft | 85 | 1.2 | 1400 |

| Natural Draft Cooling Tower | Natural Draft | 92 | 1.0 | 1300 |

| Hyperbolic Cooling Tower | Natural Draft | 88 | 1.3 | 1600 |

| Induced Draft Cooling Tower | Mechanical Draft | 93 | 1.4 | 1700 |

| Evaporative Cooling Tower | Mechanical Draft | 95 | 1.1 | 1800 |

| Dry Cooling Tower | Mechanical Draft | 80 | 0.5 | 2000 |

| Closed Circuit Cooling Tower | Mechanical Draft | 87 | 1.0 | 1900 |

| Wooden Cooling Tower | Natural Draft | 75 | 1.2 | 1250 |

| Filling Type Cooling Tower | Mechanical Draft | 89 | 1.7 | 1450 |

Performance Metrics: Efficiency Ratings for Different Cooling Tower Types

Cooling towers play a vital role in various industrial processes. Their efficiency directly impacts energy consumption and operational costs. Performance metrics are essential for assessing different tower types. The efficiency rating often varies significantly based on design and operational parameters.

A recent industry report highlighted that forced draft cooling towers average an efficiency rating of 85%. This is superior compared to counterflow designs, which typically operate around 75% efficiency. However, performance can decline under certain conditions. Factors like water quality and environmental temperature influence outcomes. Many facilities struggle with maintenance, leading to reduced efficiency over time. Regular checks are vital to ensure optimal performance.

Evaporative cooling towers also show promising metrics. Studies indicate an efficiency of around 90% under ideal conditions. Yet, achieving these numbers requires constant monitoring. Some operators overlook this, resulting in increased operational costs. The use of advanced monitoring technologies can help maintain high efficiency. Understanding these performance metrics is crucial for effective heat management in industries.

Material Considerations: Corrosion Resistance and Longevity in Cooling Towers

Cooling towers play a crucial role in heat management across various industries. When selecting a cooling tower, material considerations are essential. Corrosion resistance significantly impacts longevity. Steel and concrete are common choices, but they can face corrosion challenges. For instance, studies show that stainless steel can resist rust better than carbon steel, leading to extended operational life.

Galvanization is another method for enhancing corrosion resistance in steel towers. According to industry reports, galvanized steel can last two to three times longer than non-treated steel. This longevity is important for maintaining efficiency and reducing replacement costs. While some cooling towers are made with plastic materials, they also have limitations. Certain plastics may degrade under UV exposure, which can compromise structural integrity.

In terms of thermal performance, material selection influences heat transfer efficiency. For example, fiberglass cooling towers are lightweight and resistant to corrosion, but they may not offer the same durability as metal options. Industry data suggests that integrating mixed materials could enhance performance and lifespan. This raises questions about the ideal composition for specific applications. Understanding material properties remains a topic for continued exploration in cooling tower design.

Environmental Impact and Sustainability of Various Cooling Tower Designs

When considering cooling tower designs, environmental impact is a key factor. Some designs optimize water use to minimize waste. Others incorporate materials that have lower ecological footprints. This focus is crucial in reducing the overall environmental burden. The carbon footprint of manufacturing these structures varies significantly. Some towers are made from sustainable materials, which help in achieving better sustainability scores.

Not all cooling towers are created equal in terms of sustainability. For instance, natural draft towers may use less energy than mechanical ones. However, their large footprint can disrupt local ecosystems. On the other hand, hybrid models are becoming popular. They offer a balance between efficiency and ecological responsibility. However, the complexity of hybrid designs can pose maintenance challenges. It’s essential to weigh these pros and cons carefully.

Another aspect is the water consumption of cooling towers. Open-loop systems often waste more water compared to closed-loop systems. Water scarcity is a pressing issue. Therefore, solutions that recycle water can provide additional benefits. Some designs, however, may over-rely on technology, which could lead to unforeseen issues. Thoughtful design must prioritize the environment while remaining practical.