Unlocking the Potential of Horizontal Milling Machines for Innovative Manufacturing Solutions

In recent years, the manufacturing sector has witnessed a significant shift towards advanced machining technologies, with the horizontal milling machine emerging as a critical player in this evolution. According to a report by the International Federation of Robotics, the adoption of robotics and automation technology in manufacturing is expected to grow at a compound annual growth rate (CAGR) of 16% through 2025, underscoring the increasing importance of efficiency and precision.

Horizontal milling machines, known for their versatility and ability to handle complex geometries, present innovative solutions that not only enhance production capabilities but also improve the overall quality of machined parts. As industries seek to optimize their processes, understanding the potential of horizontal milling machines becomes essential for staying competitive in a rapidly changing market. Embracing this technology could lead to substantial reductions in operational costs, with some reports indicating savings of up to 30% in manufacturing expenses through improved machining strategies.

Horizontal milling machines, known for their versatility and ability to handle complex geometries, present innovative solutions that not only enhance production capabilities but also improve the overall quality of machined parts. As industries seek to optimize their processes, understanding the potential of horizontal milling machines becomes essential for staying competitive in a rapidly changing market. Embracing this technology could lead to substantial reductions in operational costs, with some reports indicating savings of up to 30% in manufacturing expenses through improved machining strategies.

Understanding the Fundamentals of Horizontal Milling Machines for Modern Manufacturing

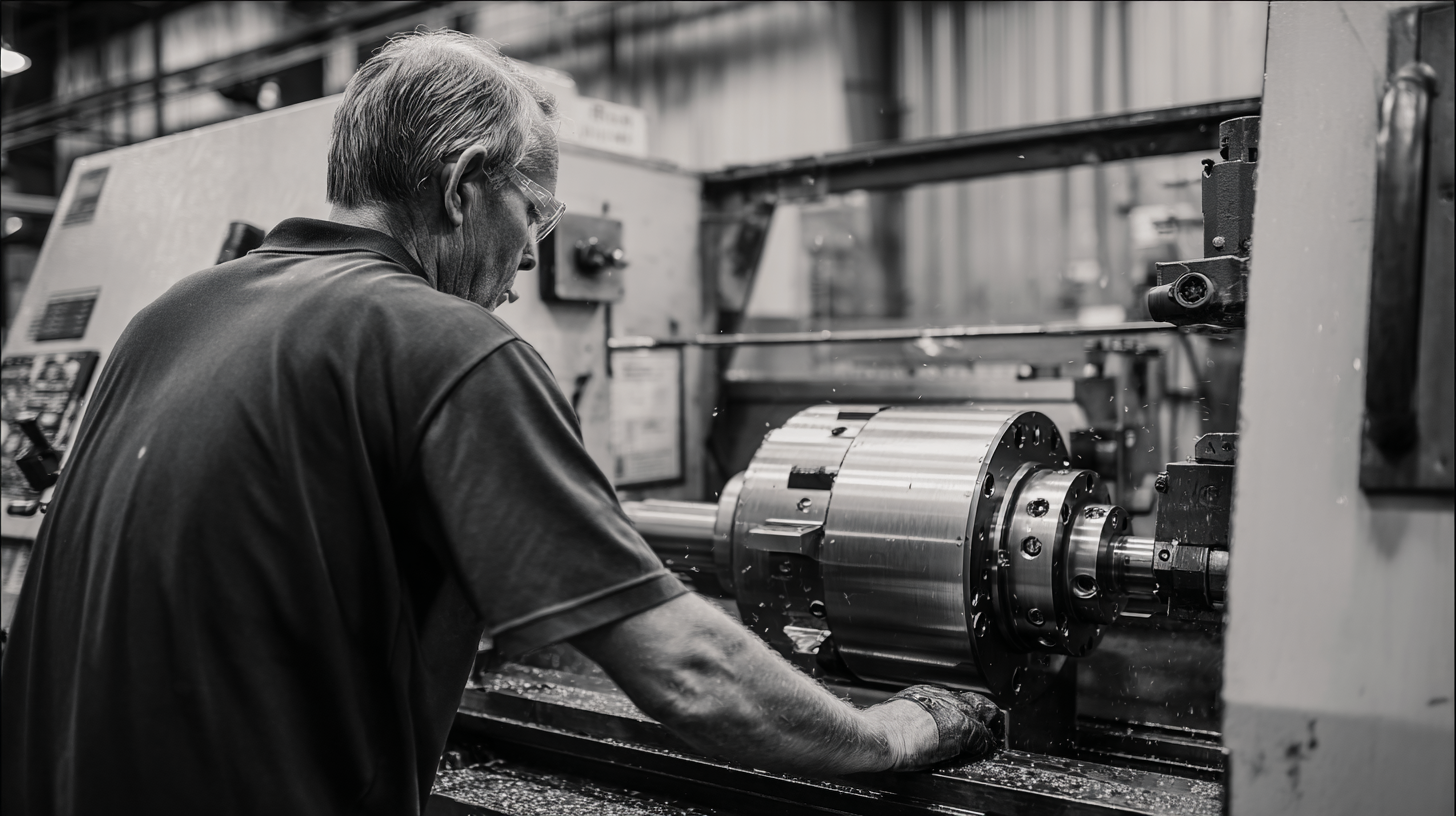

Horizontal milling machines have become a cornerstone for modern manufacturing, significantly enhancing productivity and precision in various industrial applications. The recent launch of advanced horizontal machining centers demonstrates the growing trend towards these machines, focusing on increased efficiency and reduced cycle times. With innovations in four-axis and high-speed machining, manufacturers are experiencing substantial improvements in workflow—ultimately allowing for more complex projects to be completed with greater speed.

Understanding the fundamentals of horizontal milling machines is essential for manufacturers seeking to harness their full potential. These machines offer superior chip removal capabilities and better accessibility for tooling, ensuring optimal performance in high-mix, high-repeat manufacturing environments. As demonstrated by companies successfully integrating these technologies, the shift to horizontal machining centers is not only transforming operations but also reshaping productivity metrics across the sector, enabling firms to stay competitive in a rapidly evolving market.

Identifying Key Advantages of Horizontal Milling in Innovative Production Processes

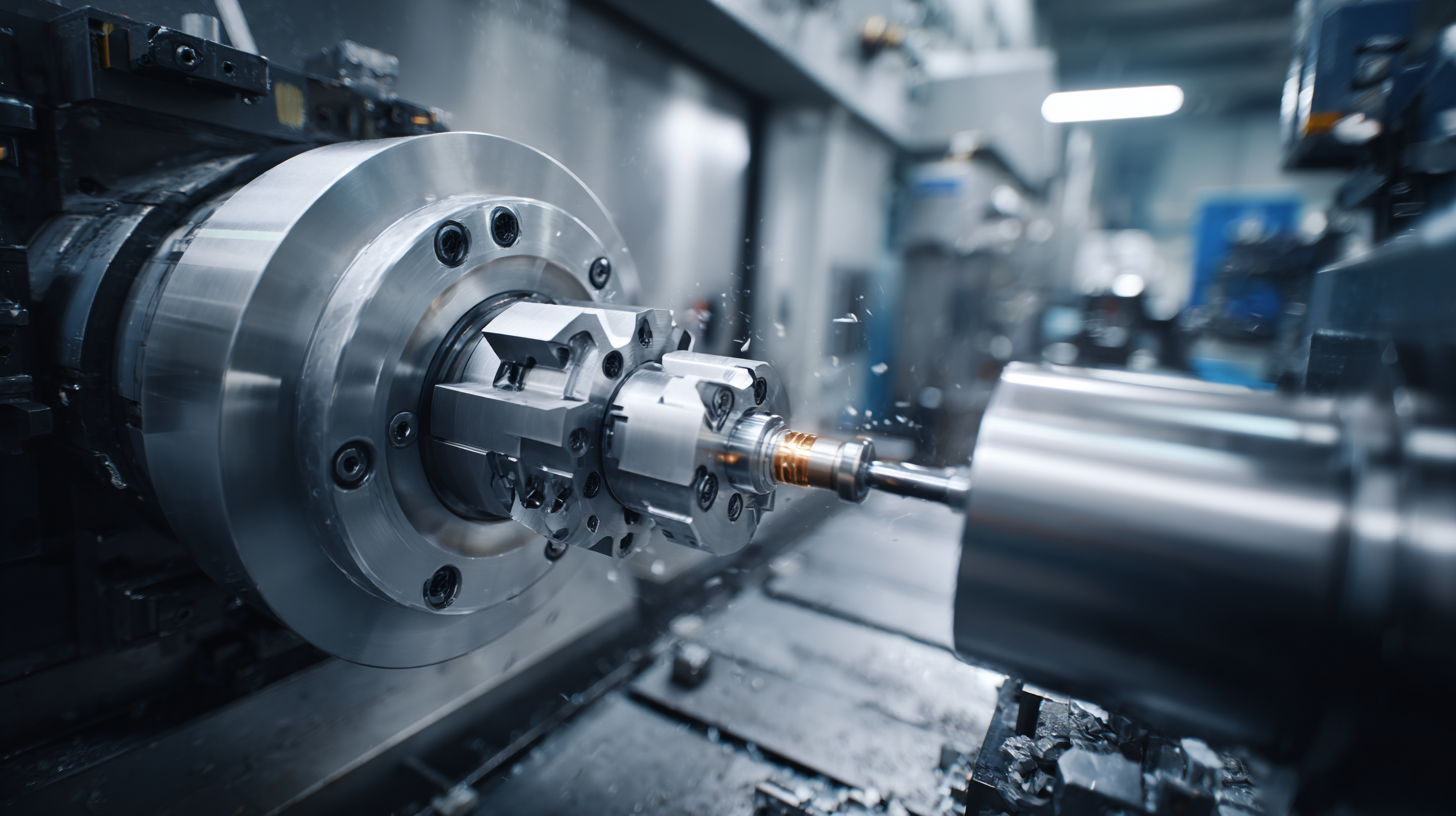

Horizontal milling machines have emerged as a vital asset in innovative production processes, particularly due to their ability to handle complex geometries and improve manufacturing efficiency. According to a 2022 report by the Association for Manufacturing Technology, the adoption of horizontal milling technology has increased operational productivity by an average of 30%, allowing manufacturers to meet rising market demands more effectively. One of the key advantages of horizontal milling is its superior chip management system, resulting in enhanced coolant flow and minimized heat generation, critical factors that lead to longer tool life and reduced downtime during production.

Furthermore, horizontal milling machines are renowned for their ability to perform multiple operations simultaneously. This capability significantly optimizes machining time and enhances precision, as highlighted in a recent industry analysis by Grand View Research. The report noted that companies utilizing horizontal milling reported a 25% improvement in dimensional accuracy, which is crucial for industries such as aerospace and medical device manufacturing, where tolerances are stringent. As manufacturers continue to seek innovative solutions, the strategic implementation of horizontal milling technology could be the key to unlocking new levels of efficiency and product quality.

Exploring Advanced Techniques for Maximizing Efficiency in Horizontal Milling Operations

Horizontal milling machines are at the forefront of innovative manufacturing solutions, particularly as industries seek to maximize efficiency in their operations. By leveraging advanced techniques in horizontal milling, manufacturers can streamline processes and reduce waste, paving the way for more sustainable production practices. The integration of machine learning technologies into milling operations is one promising avenue that shows potential for significant efficiency gains. For instance, real-time data analytics can optimize cutting parameters, monitor tool wear, and predict maintenance needs, ultimately leading to enhanced productivity.

Additionally, the exploration of hybrid systems that incorporate both traditional and emerging technologies can further elevate the capabilities of horizontal milling machines. Techniques such as improved cooling systems and advanced cutting tools are critical for maximizing performance while ensuring sustainability. The industry’s focus on ethical practices and innovative solutions reflects a broader trend towards prioritizing environmental responsibility. By embracing these advanced methods, manufacturers can not only enhance operational efficiency but also contribute to sustainable practices that align with contemporary market demands.

Integrating Technology: How CNC and Automation Enhance Horizontal Milling Capabilities

The integration of CNC technology and automation into horizontal milling machines has revolutionized the manufacturing landscape, leading to significant enhancements in productivity across various industries. As companies strive to optimize their operations, the implementation of advanced digital manufacturing technologies has proven essential. A recent market analysis report highlights that the global market for 3-way pilot-operated directional control valves is projected to reach USD 892.6 million by 2035, growing at a compound annual growth rate (CAGR) of 3.4%. This growth reflects the increasing adoption of automation-driven solutions in industrial applications, which directly influences the performance and capabilities of horizontal milling machines.

By leveraging CNC technology, manufacturers can achieve lower production costs and improved precision in machining tasks. The automation aspect further facilitates real-time monitoring and quality control, resulting in a streamlined workflow. As a result, businesses that incorporate these technologies are better positioned to innovate and respond to market demands swiftly. The synergy between horizontal milling capabilities and sophisticated control systems not only boosts efficiency but also opens the door to novel manufacturing solutions that were previously unattainable.

Integration of Technology in Horizontal Milling Machines

This chart illustrates the integration of technology in horizontal milling machines, highlighting key performance metrics such as CNC capability, automation level, precision, efficiency, and cost reduction. A higher value indicates better performance in that area, showcasing the innovative manufacturing solutions enabled by these advancements.

Case Studies: Successful Applications of Horizontal Milling in Innovative Manufacturing Solutions

Horizontal milling machines are gaining traction in various manufacturing sectors due to their versatility and efficiency. A report by MarketsandMarkets indicates that the global horizontal milling machine market is projected to grow at a CAGR of 7.5% from 2020 to 2025, driven by the increasing demand for precision engineering solutions across industries, including aerospace and automotive. Case studies have highlighted how companies like Boeing have leveraged these machines for their ability to handle complex geometries and large workpieces, resulting in enhanced productivity and reduced lead times.

Innovative applications of horizontal milling machines extend beyond traditional manufacturing. For instance, a notable case study involving a medical device manufacturer demonstrated a 30% reduction in production time by using horizontal milling for intricate component machining. This adaptation not only improved machining accuracy but also paved the way for cost-effective mass production. Additionally, automotive firms have benefited from the flexibility offered by these machines in producing high-quality parts with tighter tolerances, reducing waste and optimizing resource utilization, as evidenced by a significant decrease in machining errors reported in recent performance audits.

Related Posts

-

Discover Unmatched Manufacturing Excellence with the Best Horizontal Milling Machine from Leading Chinese Factories

-

Exploring the Future of Horizontal Milling Machines at the 138th Canton Fair 2025: Industry Insights and Trends

-

Elevating Global Standards with Premium CNC Machine Parts from China

-

China's Best CNC Vertical Machining Center for Global Buyers Trust in Quality and Innovation

-

Exploring Top Alternatives to the Best Vertical CNC Machine for Global Buyers

-

Why CNC Turning Machines Are Essential for Modern Manufacturing Efficiency