Unlocking Precision: How Horizontal Milling Machines Transform Modern Manufacturing

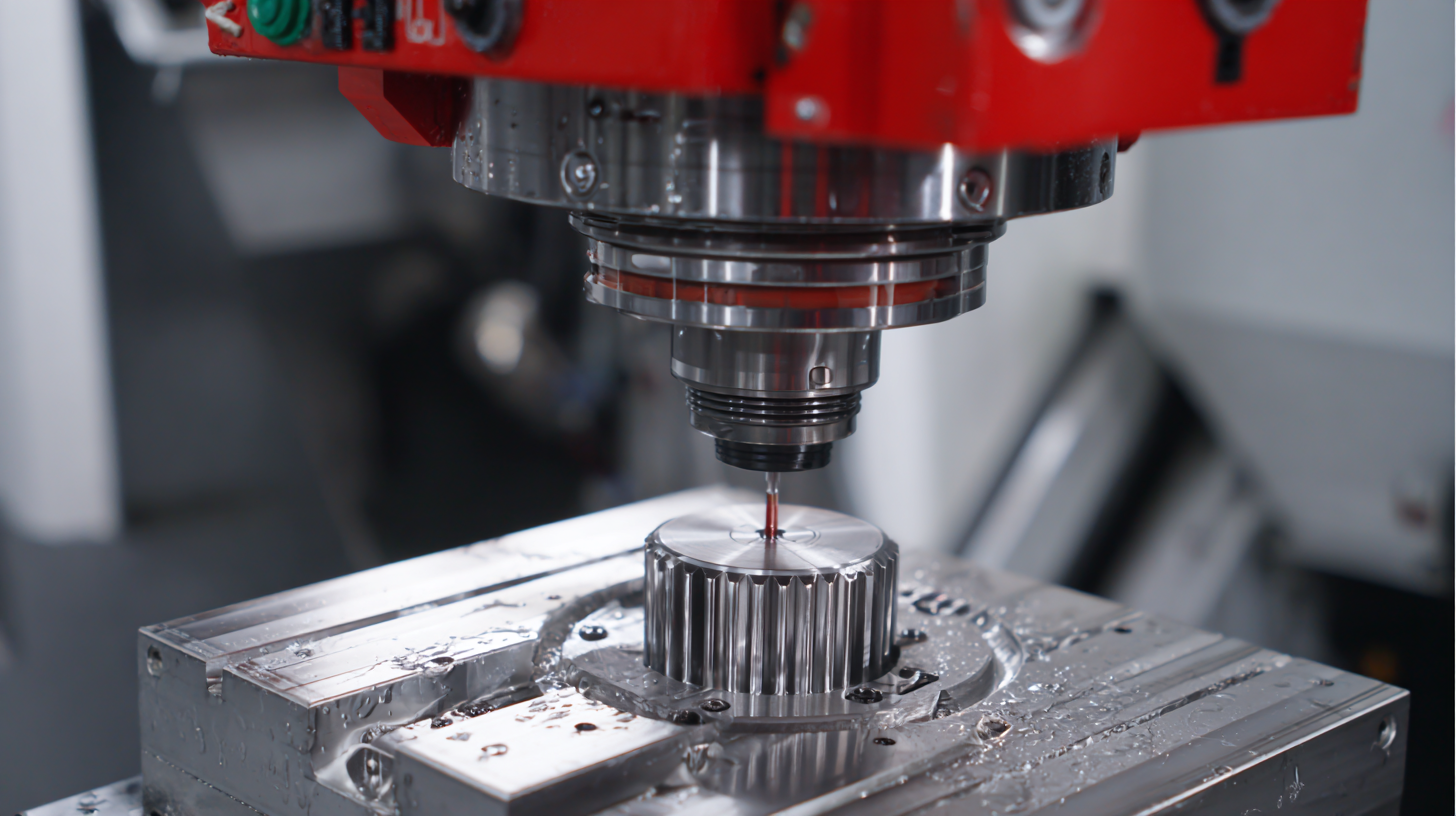

In the realm of modern manufacturing, the advent of technology has significantly transformed traditional processes, paving the way for enhanced precision and efficiency. At the forefront of this transformation is the horizontal milling machine, a pivotal tool that revolutionizes how materials are shaped and refined. Unlike its vertical counterpart, the horizontal milling machine offers a range of capabilities that enable operators to achieve intricate designs with unparalleled accuracy. This machine's unique design allows for better chip removal and improved cutting conditions, making it ideal for heavy-duty tasks. As industries increasingly strive for innovation and excellence, understanding the mechanics and advantages of horizontal milling machines becomes essential. This article delves into the mechanics behind these sophisticated machines, exploring how they unlock new manufacturing potentials and elevate operational standards in today's competitive landscape.

The Evolution of Horizontal Milling Machines in the Manufacturing Sector

The evolution of horizontal milling machines has been a cornerstone in the transformation of the manufacturing sector. Initially developed in the early 19th century, these machines have undergone significant technological advancements, transitioning from manual to automatic operations. The shift towards CNC (computer numerical control) technology marked a pivotal moment, enabling manufacturers to achieve higher precision and repeatability in their processes. This technological leap has allowed for the production of complex components that were once deemed impractical, thereby expanding the scope of what is possible in manufacturing.

In recent years, horizontal milling machines have integrated advanced features such as real-time monitoring systems and adaptive control, further enhancing their efficiency and reliability. These innovations not only minimize waste and reduce production times but also improve the overall quality of the final product. As industries increasingly demand customization and faster turnaround times, the horizontal milling machine stands out as a versatile and essential tool, embodying the spirit of modernization in manufacturing processes. This evolution encapsulates a broader shift towards automation and precision, significantly impacting various sectors including aerospace, automotive, and medical device manufacturing.

Key Advantages of Horizontal Milling Machines Over Vertical Alternatives

Horizontal milling machines offer distinct advantages over their vertical counterparts, primarily in terms of precision and efficiency. One of the key benefits is their ability to handle heavier and larger workpieces more effectively. The horizontal orientation allows for better chip removal, reducing the risk of clogging and ensuring smoother operations. This is particularly beneficial in manufacturing processes that require high volumes of material removal, as it enhances productivity and reduces downtime.

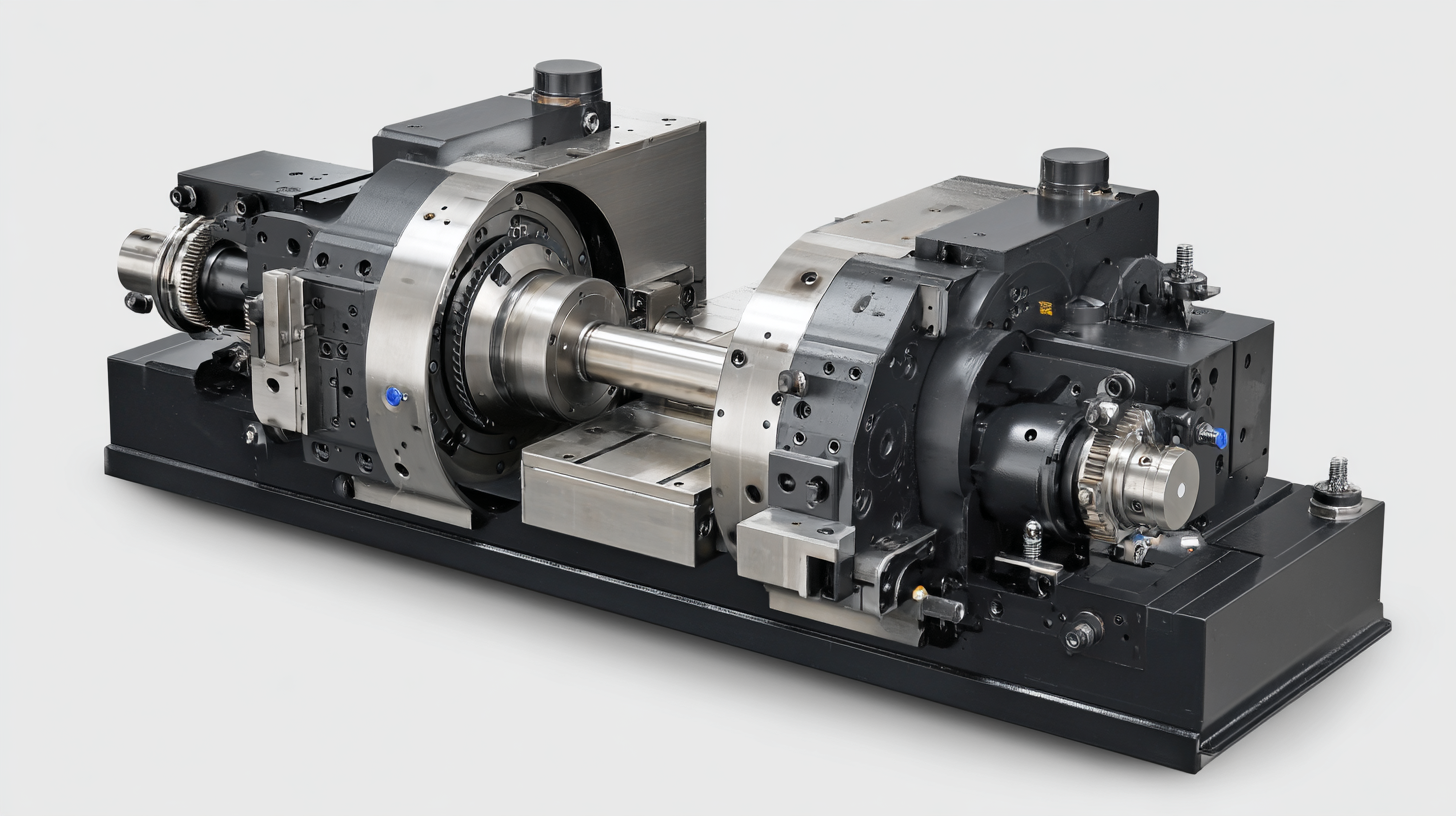

Additionally, horizontal milling machines provide superior versatility and can accommodate a wider range of tooling options. This flexibility is crucial in modern manufacturing environments where adaptability is essential to meet diverse production needs. With the capability to perform complex operations like slotting, drilling, and contouring in a single setup, these machines significantly reduce the time and effort required for setups and changeovers. Consequently, manufacturers can achieve better accuracy and maintain tighter tolerances, leading to higher quality finished products.

Unlocking Precision: Comparison of Key Advantages of Horizontal Milling Machines Over Vertical Alternatives

Impact of Precision Machining on Production Efficiency and Cost Reduction

Horizontal milling machines have become pivotal in modern manufacturing,

especially when precision machining is at the forefront of production efficiency. Their ability to deliver

high accuracy while operating on larger workpieces has transformed

various industries. With the implementation of these machines, manufacturers can achieve tighter

tolerances, ensuring that every component meets strict quality standards. This accuracy not only optimizes

production flows but also significantly reduces waste, making the manufacturing process more cost-effective.

Horizontal milling machines have become pivotal in modern manufacturing,

especially when precision machining is at the forefront of production efficiency. Their ability to deliver

high accuracy while operating on larger workpieces has transformed

various industries. With the implementation of these machines, manufacturers can achieve tighter

tolerances, ensuring that every component meets strict quality standards. This accuracy not only optimizes

production flows but also significantly reduces waste, making the manufacturing process more cost-effective.

Tips: To enhance the efficiency of your horizontal milling operations, consider

regularly maintaining your machinery to avoid costly downtime. Additionally, investing in high-quality cutting

tools can improve precision and longevity, ensuring better overall performance.

Moreover, as businesses strive to remain competitive, the adoption of advanced horizontal milling technology

helps reduce lead times. The capability of these machines to perform multiple operations — such as milling,

drilling, and tapping — simultaneously streamlines production. This versatility leads to shorter production

cycles and aids in minimizing labor costs, allowing manufacturers to reallocate resources towards

innovation and growth.

Tips: Don't overlook the importance of operator training. Skilled operators can

maximize the potential of horizontal milling machines, leading to improved output and efficiency. Consider

implementing a continuous education program to keep your team updated on the latest machining techniques and technologies.

Industry Statistics: Growth Trends in Horizontal Milling Machine Adoption

The adoption of horizontal milling machines is set against a backdrop of significant growth in the broader CNC machine market. Projections indicate that the global CNC machine market size will soar from $101.22 billion in 2025 to $195.59 billion by 2032, reflecting a robust compound annual growth rate (CAGR) of 9.9%. This upsurge highlights the increasing reliance on precision manufacturing technologies that enhance efficiency and productivity in various industries.

Moreover, specific segments such as the double head lathes market are witnessing even more dramatic growth, with expectations of rising from $2.1 billion in 2025 to $8.2 billion by 2035, achieving a staggering CAGR of 14.6%. This indicates a strong trend towards investment in advanced machining solutions, which play a critical role in achieving higher precision and adaptability in manufacturing processes. As industries continue to adapt to evolving demands, the integration of horizontal milling machines will be pivotal in driving innovation and operational excellence.

Unlocking Precision: How Horizontal Milling Machines Transform Modern Manufacturing

| Year | Global Market Size (Million $) | Adoption Rate (%) | Growth Rate (%) | Key Industries Using Horizontal Milling Machines |

|---|---|---|---|---|

| 2021 | 2,300 | 25% | 5.5% | Aerospace, Automotive, Electronics |

| 2022 | 2,580 | 30% | 6.4% | Medical Devices, Machine Tool Manufacturing |

| 2023 | 2,900 | 35% | 8.9% | Defense, Energy, Consumer Goods |

| 2024 | 3,200 | 40% | 10.3% | Construction, Robotics, Telecommunications |

Future Innovations: How Technology is Shaping Horizontal Milling Capabilities

As technology continues to advance, the capabilities of horizontal milling machines are evolving at an unprecedented pace. According to a recent report by Mordor Intelligence, the global CNC milling machine market is projected to grow at a CAGR of 6.25% from 2021 to 2026, driven by the increasing demand for precision manufacturing. This growth is markedly influenced by innovations in software and automation technologies that streamline the milling process, reducing waste and enhancing productivity. Features such as adaptive machining and real-time monitoring enable manufacturers to achieve tolerances that were once considered unattainable.

Furthermore, the integration of Artificial Intelligence (AI) and Internet of Things (IoT) technologies into milling machines is revolutionizing production workflows. A study from PwC indicates that organizations implementing smart manufacturing solutions can improve operational efficiency by up to 30%. These innovations not only enhance the accuracy of horizontal milling operations but also provide actionable insights from data analytics, enabling manufacturers to make informed decisions that further refine their processes. As the industry continues to embrace these advancements, the future of horizontal milling machines promises to be even more transformative, paving the way for unprecedented levels of precision and efficiency in modern manufacturing.

Related Posts

-

Discover Unmatched Manufacturing Excellence with the Best Horizontal Milling Machine from Leading Chinese Factories

-

Unlocking the Potential of Horizontal Milling Machines for Innovative Manufacturing Solutions

-

Revolutionizing Precision Engineering with CNC Horizontal Boring Mills

-

Overcoming Common Issues in CNC Machine Parts Manufacturing and Supply

-

Unveiling the Technical Specifications of the Best Vertical CNC Machines for Global Buyers

-

Overcoming Global Standards Challenges: The Search for the Best Milling Machine